Steady Supply of Parts Enhances Efficiency of Robotic Cells

CNC machine tending has developed into one of the more common uses of collaborative robots in manufacturing and production. Explained simply, machine tending is the process of loading and unloading parts into a computer numerical control (CNC) machine. This process was traditionally handled by a human worker.

Manufacturers use CNC machines (lathes and milling machines for example) to work or finish raw parts and materials. Workers would take the raw part, place it in the machine and then remove it once the machine had done its work. However, as qualified employees have become harder to find and keep, modern manufacturers and production facilities have turned more and more to robotics to keep CNC cells operating at capacity.

Collaborative robots (cobots) have been the solution for many looking to automate CNC processes. Cobots are force-limited robots that can be used without machine guarding, and placed beside other machinery or a person to perform repeatable tasks without the need to be fenced off from the surrounding production environment.

Using cobots in CNC machine tending allows greater efficiency in a key step of the manufacturing process. When production is running around the clock, machine tending enables the process to run continuously as the cobot loads and unloads efficiently and consistently.

But there is always a need for greater efficiency. Manufacturing activity increased recently, indicating that the underlying demand remains solid, and production lines will continue to look for solutions to meet those requirements. When it comes to CNC machine tending, the need is clear: A continuous flow of parts is essential to making the most out of these robotic investments.

The ability to set up a CNC machine tending cell with parts to last an entire shift, without the need to stop the flow to refill the raw parts in the cell’s work area, empowers greater production and efficiency from cobot-worked elements.

Forward-Thinking with Feedall: As a leader in industrial automation, we’re constantly examining new developments, including bin picking vision systems. Learn more here.

Achieve More Efficient CNC Machine Tending with Feedall

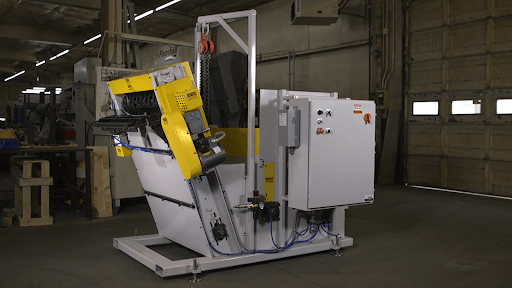

Feedall Automation delivers expertise in dependable, high-volume automation equipment, with the ability to customize each piece of machinery to the specifications of your application or task. This is particularly valuable when crafting solutions to serve CNC machine tending, where efficient, consistent, steady part feeding augments the capabilities of a robot-loaded cell.

Our comprehensive line of bar and shaft feeders are well suited to work with and enhance the capacity of CNC machine tending cobots. Armed with a deep reservoir of hands-on experience, our engineering team delivers reliable solutions for your part feeding needs ensuring your robotic cells have no shortage of parts ready to be processed.

And while we’re showcasing bar, tube, and billet feeding machinery, Feedall can qualify any part with a feeding solution. Our in-house manufacturing capabilities give us control over customization options while leading to cost savings for customers. It empowers us to deliver premium part feeders on time and on budget, with optional value-adding features such as additional part transfers and pushers, part qualifiers, cross-feed conveyors, and powered wheels.

Magazine Style Automatic Bar Feeders

When it comes to feeding a CNC machine tending cell, Feedall’s selection Magazine Style Automatic Bar Feeders are perfectly suited to optimally provide fresh parts throughout an entire shift. Capable of delivering parts to many secondary applications — like centerless grinders, induction heaters, etc. — these part feeders eliminate delays for robotic cells with a larger part capacity than typically incorporated into most machine tending units.

With their magazine capacity, these loaders minimize handloading parts into secondary operations, enabling increased unattended run time at a decreased cost. Instead of handloading another batch of parts — whether that’s a dozen or two — when needed, the use of Feedall’s magazine-style automatic bar feeders can continuously keep the CNC machine tending robot supplied throughout an entire shift or day. This frees personnel to oversee more cells or tackle other higher-value tasks and maximizes the efficiency of machine tending units.

Feedall’s Model 1700 feeder brings unparalleled versatility while adding efficiency. Hand wheels are implemented for quick and simple adjustments for length and diameter changes of the parts fed. Conveyor systems can be integrated into the design easily. It’s capable of handling part diameters ranging from ¼ to 2 inches, and lengths between 2 and 28 inches. There are model options to serve smaller parts (Model 1750) and heavy-duty versions for bars and tubes up to 4 inches in diameter and 12 feet in length.

View the 1700-D Model | See It In Action

Auto Loaded Bar Feeders

For larger or longer bars and billets, Feedall’s Auto Loaded Bar Feeders take advantage of hoppers to serve up steady streams of parts to CNC machine tending stations. The Model 2200 series offers many capabilities to further enhance the efficiency of the part feeding process:

- Optional drop-bottom bins mean handloading isn’t required

- Air-operated mechanisms reduce noise

- Proprietary custom cleats perfectly capture parts

- Orients parts organically, and prevents misoriented parts from being recirculated

- While oriented parts accumulate, they are lifted and escape one at a time

- Easy monitoring of the part queue, with automatic shutdown of the conveyor as necessary

View the Model 2236 | See It In Action

Ready to Get Started?: If you’re interested in specifics of what Feedall Automation has to offer, contact us today to get a free quote or more information about what we can do for you.

Trust Feedall for Innovative Automation Solutions

At Feedall, we believe in acting as a true partner, working with you to learn about the parts you produce, the size and scope of your facility, and then fulfilling your requirements with equipment designed to maximize efficiency and production. We provide custom solutions and then offer value-adding tooling to further tailor the equipment for your applications — including CNC machine tending.

From bulk material handling equipment to essential conveying systems and more, Feedall helps you get the most out of your manufacturing operations. Our customized equipment is also built to last and comes backed with support services, part availability, and a best-in-class repair program. In a rapidly-changing and challenging world, we’re the partner that provides a competitive advantage through automation.

Connect with us today to discuss how our automation solutions can optimize your production facility.