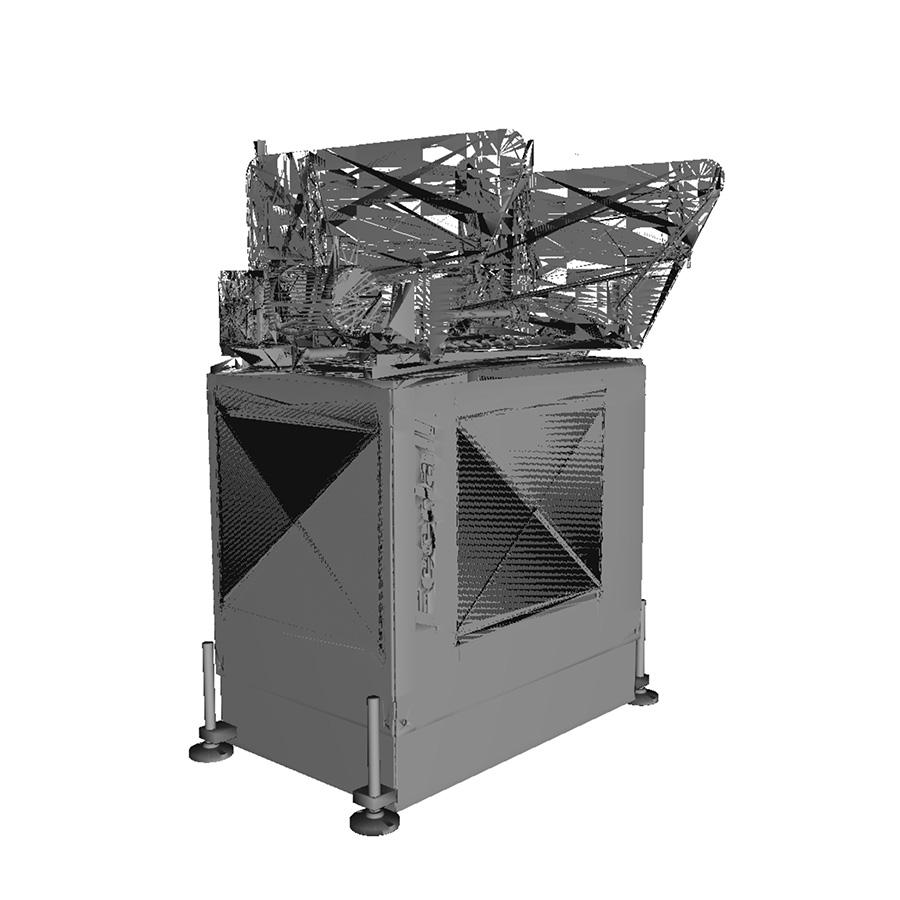

Retriever

1700

Feedall Proves Unparalleled Magazine Bar Feeder Excellence

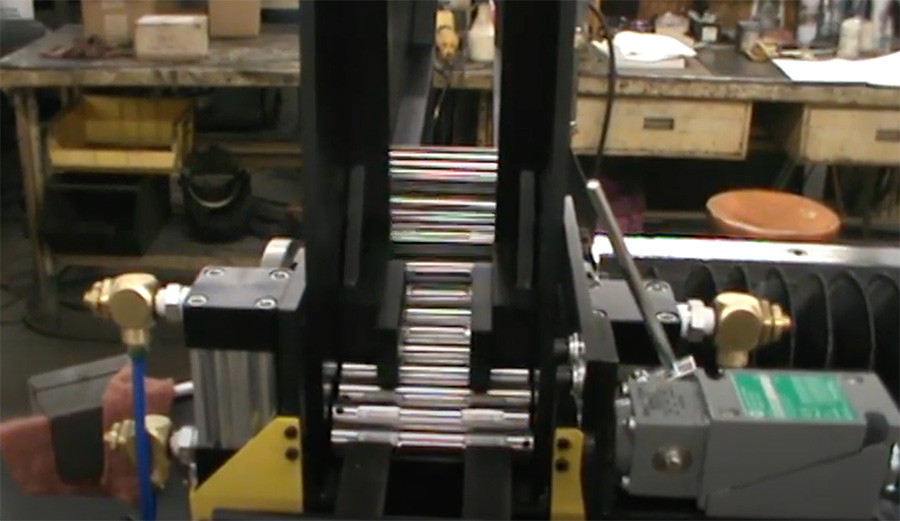

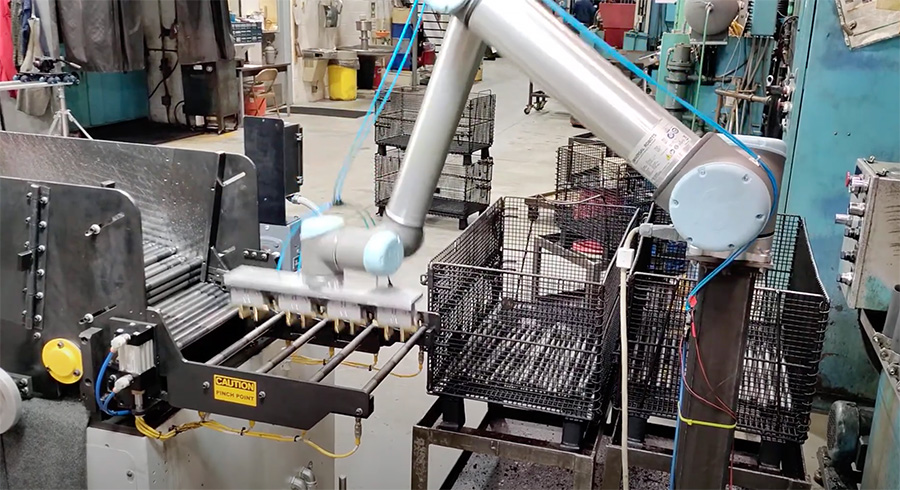

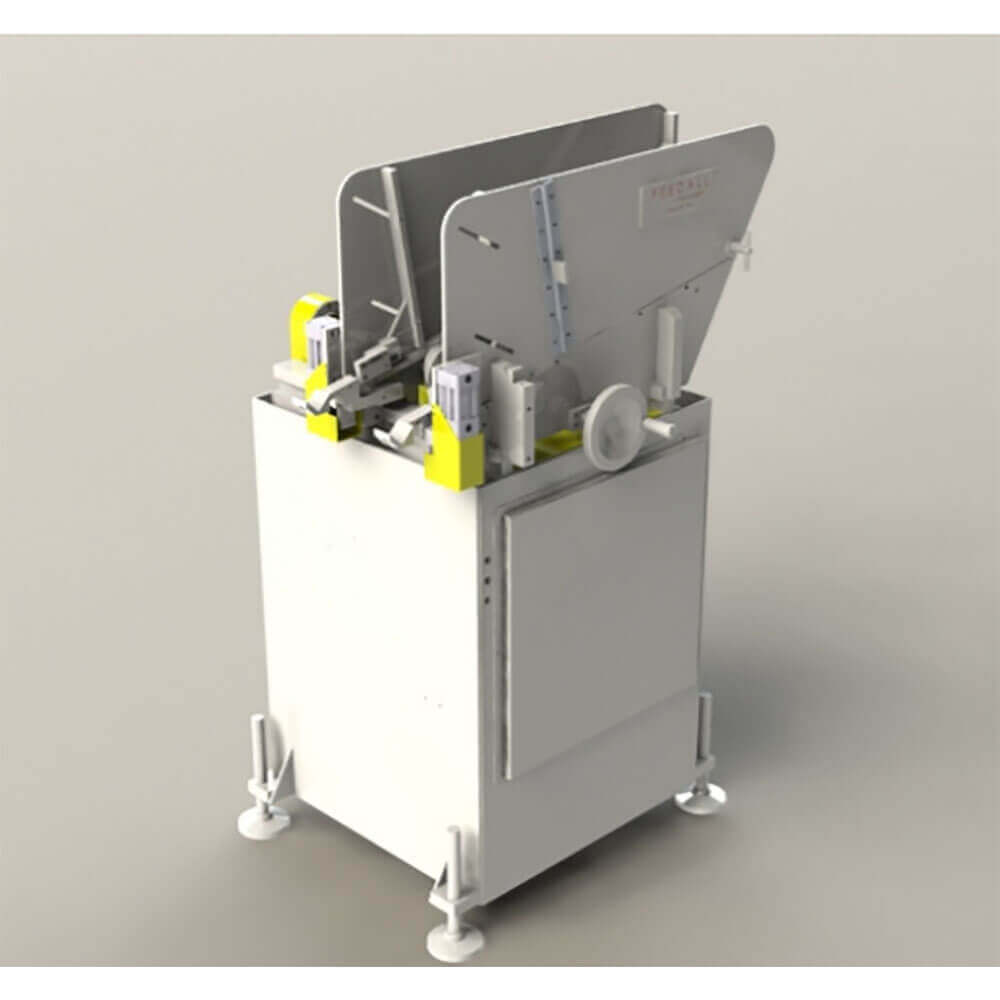

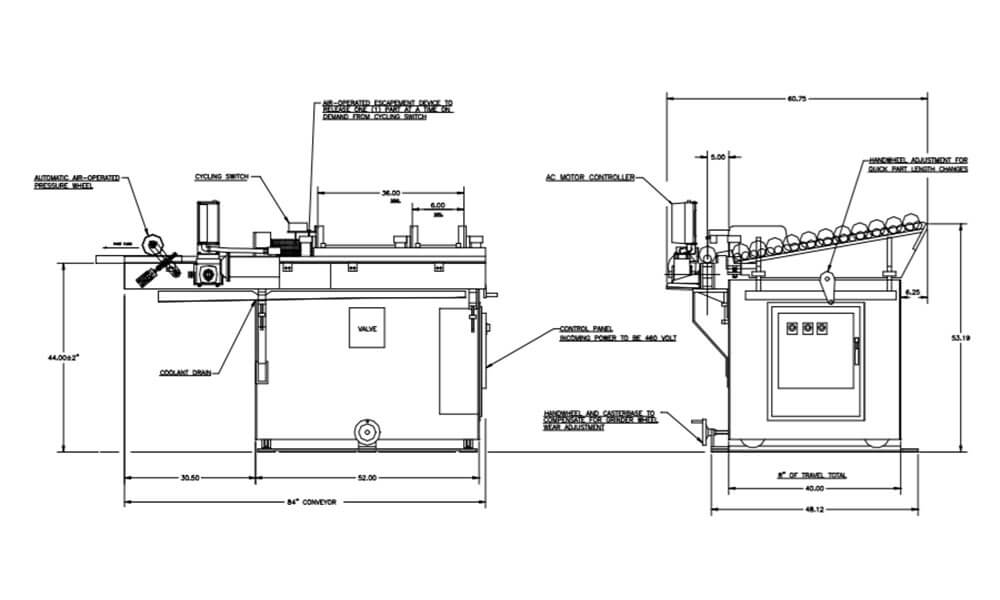

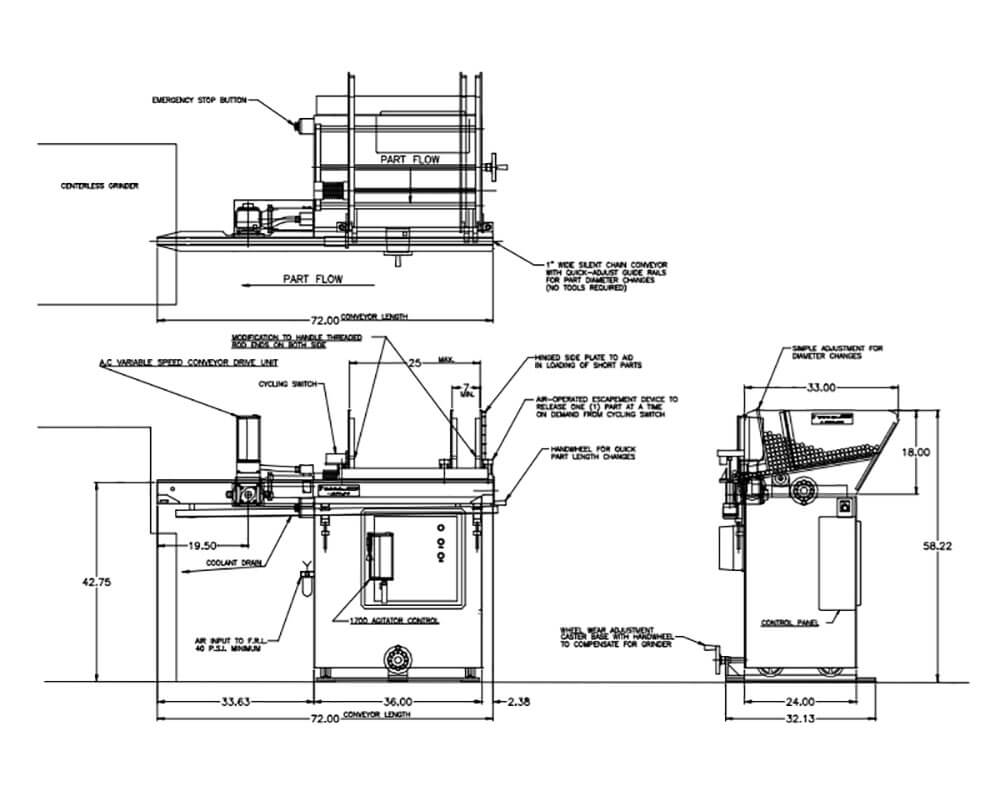

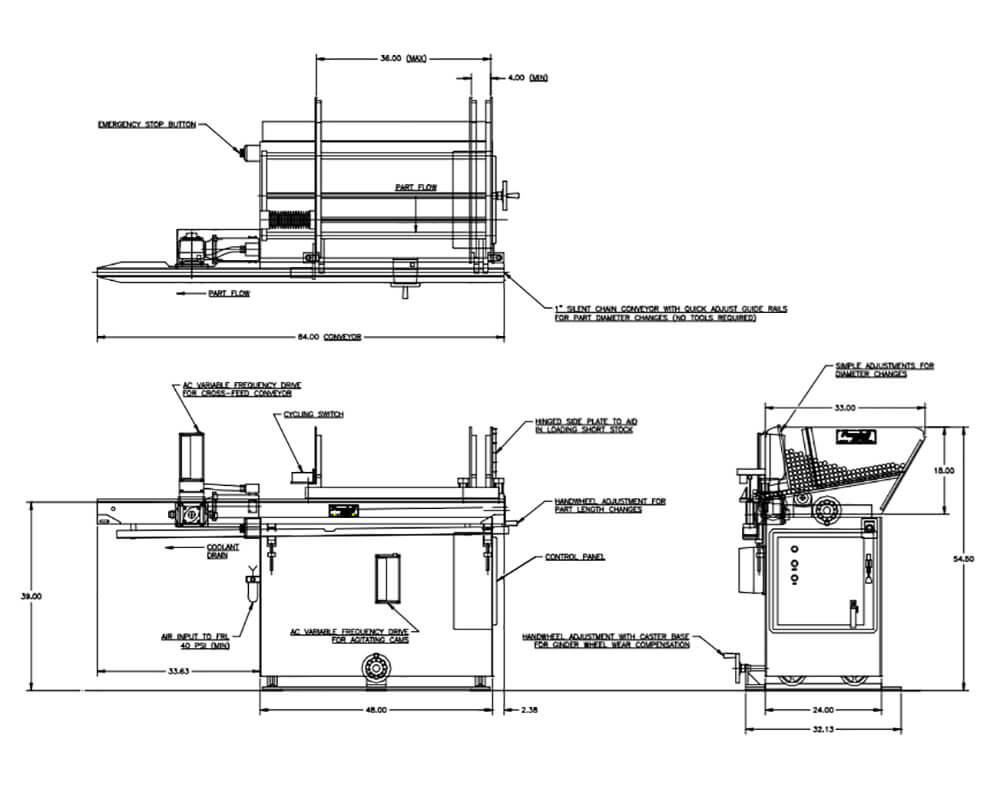

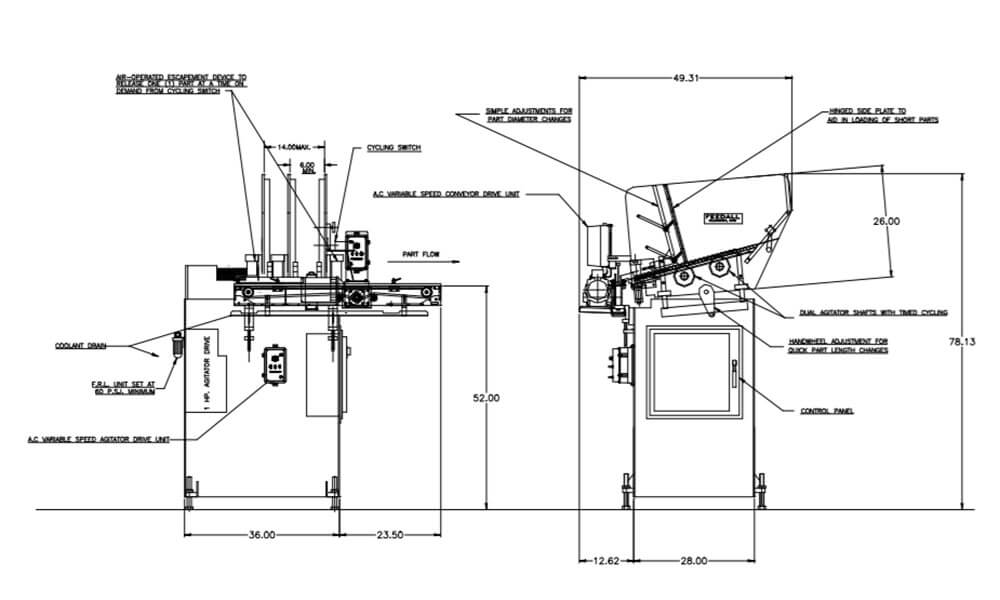

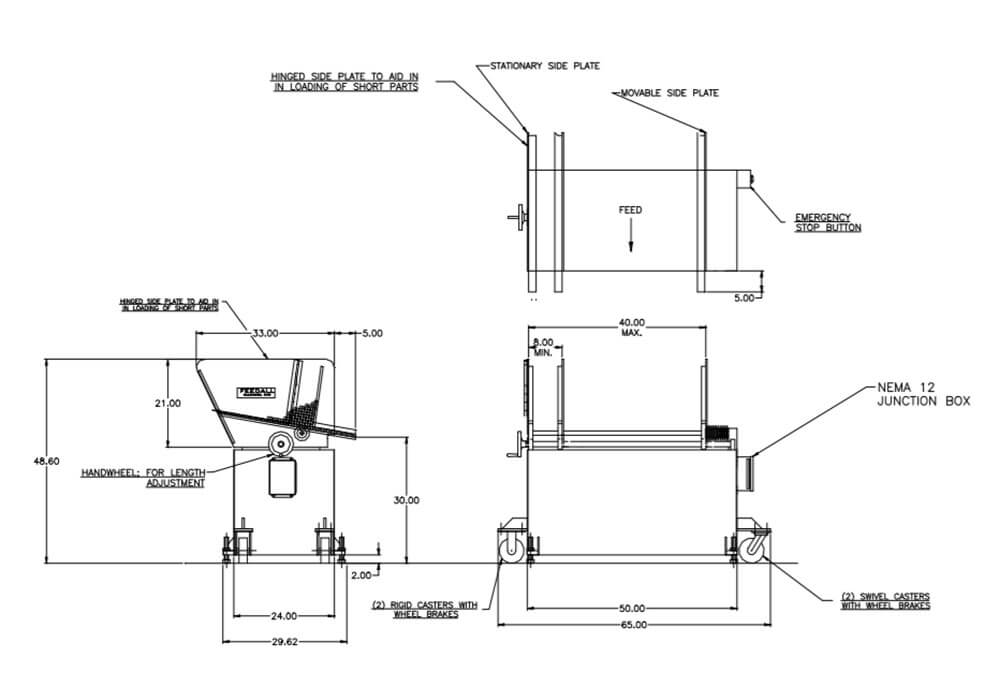

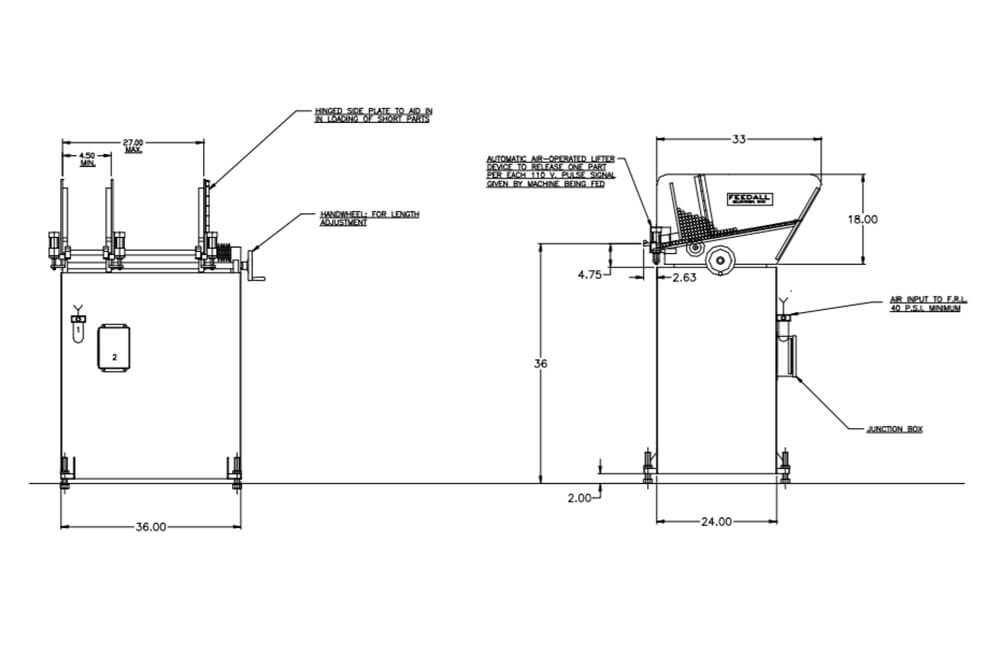

Feedall Automation has a long history of providing bar feeders of the highest quality, with each capable of customization options that allow it to seamlessly integrate in your production line and address your unique application needs due to its flexible design. The Retriever 1700 is our standard magazine bar feeder that minimizes the required handloading of tubes, bars and similar shaped parts into secondary operations. Easily adaptable, it can be tailored to suit a wide variety of applications — from robot loading cells to a long-list of manufacturing processes.

Every Retriever unit is built to last and comes with a long list of optional features to create the ideal bar feeder set up for your facility — and the most widely capable feeder available.

Overview

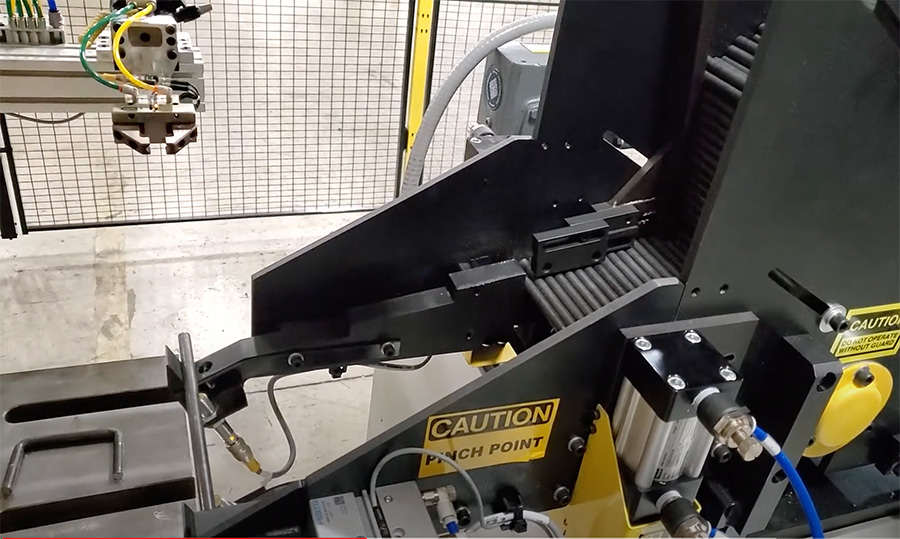

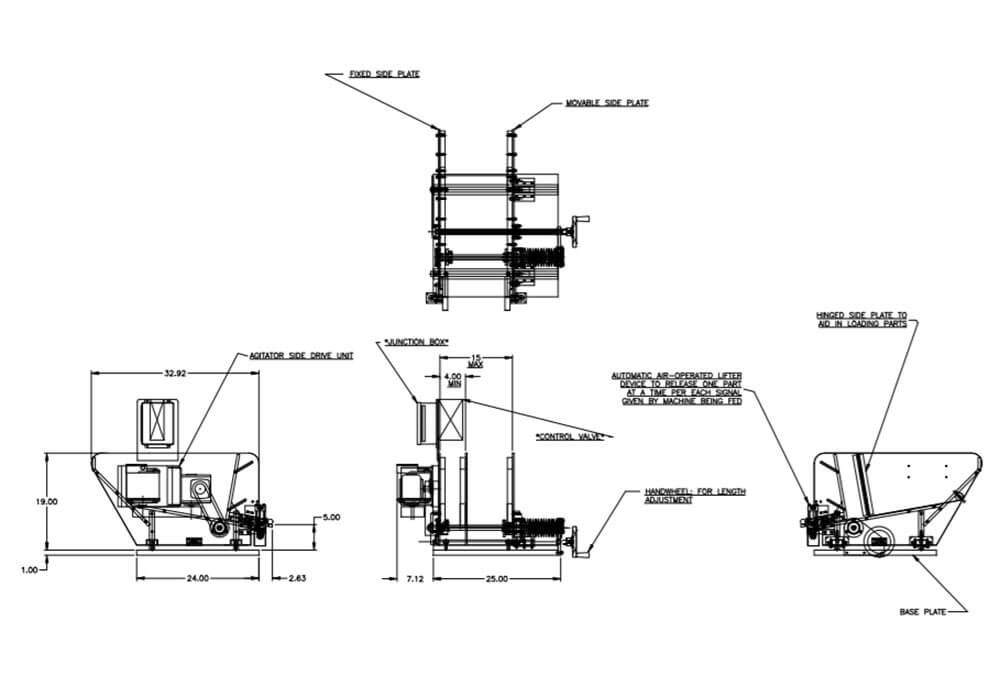

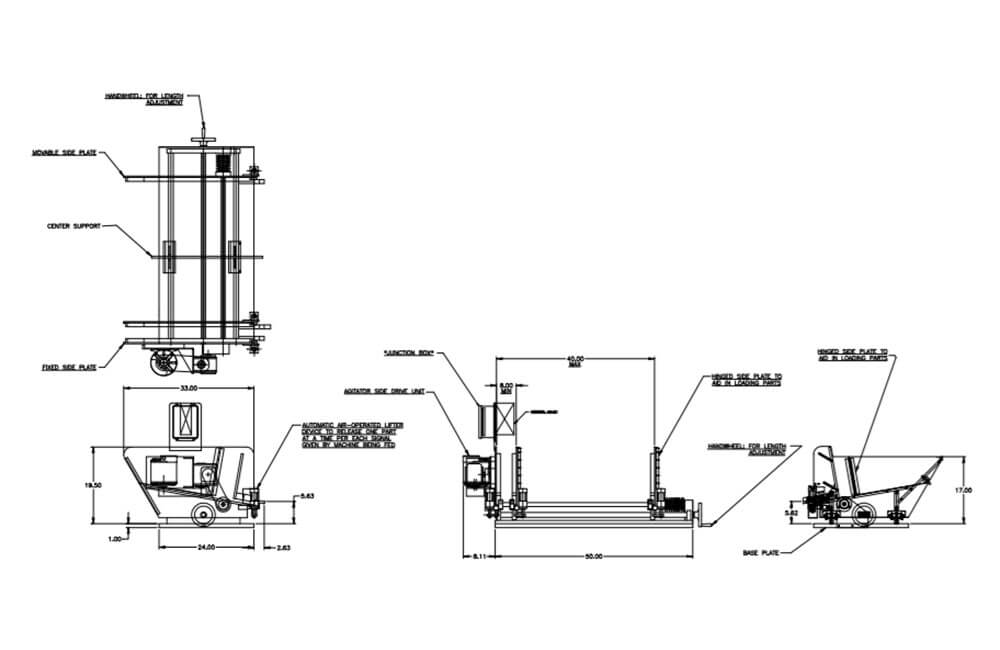

The Retriever 1700 is our standard magazine-loaded bar feeder and handles a range of part sizes ranging in diameters from ¼ inches to 2 inches and from 4 inches to 28 inches in length. This standard unit was built specifically to serve up parts for secondary operations. Each part is singled out to an exit ramp, conveyor or V-nest to provide exact part orientation and location for robotic pick and place operations. Heavy duty magazines for robotic pick and place can handle larger part sizes (up to 4 inches in diameter and 12 feet in length).

Every Feedall bar feeder can be outfitted with a host of additional options and features. For instance, the Retriever 1700 has heavy duty magazine options, bench-top mounting capability, and attached conveyors systems. Other features include:

- Track and guide extensions

- Dual lifters

- Center supports for longer parts

- Dual cam shafts for better part flow

- Caster track for grinder wheel wear compensation

- Drip pans to return coolant back to machine

- 36 inches – 144 inches length capacity

- Centering type discharge magazine