Achieve Durability and Dependability with the Right Partner

Bar feeders are essential when working with bars, billets, tubes, and similarly shaped parts, whether it’s at the start of a production line and introducing such parts to the initial station, or moving parts to key secondary operations such as an assembly machine, thread roller, and grinders. However, bar feeder problems can upset the balance of not only a single cell but the entire production line.

Ideally, any parts feeder should maintain a steady flow of parts; it’s a proven way to reach production goals and benchmarks for overall consistency in a manufacturing environment. Automated parts feeders further optimize the process by performing the same task every time, consistently. Without automation, it might take as many as three employees to operate a centerless grinding station for instance; one to cue up the part to the station, a second to guide the part through the grinder itself, and a third to exit the part and move it on to the next cell.

With automation, those same three employees could cover additional lines — meaning more parts are produced or worked per cycle — or address other areas of the factory floor.

But different styles of bar feeders can also bring issues that are detrimental to the goals of more efficiency and better production. For instance, vibratory bowl feeders use a vibrating drive unit to orient and move parts along an inclined track to the end of the bowl. But the issues with vibratory bowls include a lack of functionality with longer or heavier parts (they are typically used with smaller parts only), high maintenance, a lack of reliability, and the inability to execute quick changeovers given the design of the machinery. Whether it’s a mechanical breakdown, jamming issues, or the maintenance to prevent both, a 2018 survey conducted by Feedall Automation cited maintenance and downtime as the biggest concerns with this part feeding method.

Meanwhile, step feeders are also often used for bar feeding but come with their own issues. Step feeders typically feed bulk parts from a hopper bin by carrying the parts up to the tooling feature with a combination of moving and stationary reciprocating plates, shelves, or ‘steps.’ But stepper, or ladder, feeders tend to be part-specific, suffer from their own jamming issues, and are more effective for shorter or smaller cylindrical parts. Changing over from one size — either in diameter or length — is a more involved process that can eat away at efficiency.

Avoiding these kinds of bar feeder problems should be a goal for every production line and manufacturing environment. Working with a leader in automation equipment, with a long track record of proven solutions, will uncover opportunities that increase efficiency, versatility, and reliability.

The Feedall Difference: Ready to work with the industrial automation leader for part feeders and loaders? Contact Feedall Automation to begin discussing your next solution.

Avoid Unnecessary Issues with Automatic Bar Feeders from Feedall

Feedall offers the most advanced line of custom automation equipment, with each capable of being customized to your specifications. As experts in reliable, high-volume automation equipment, we produce a wide array of part-feeding solutions in our role as a leading industrial automation company.

That expertise includes an extensive line of bar and shaft feeders that eliminate problems, can be equipped with value-adding features, and add efficiency to your manufacturing capabilities. Our engineering team has extensive hands-on experience in delivering durable solutions to your part feeding needs — no matter how complex.

Our in-house manufacturing capabilities give us control over custom parts-making and lead to cost savings for customers. It enables us to deliver premium bar and shaft feeders on time and on budget, and with optional functionality extras like cross-feed conveyors, powered wheels, part qualifiers, and part transfers and pushers.

Magazine Style Automatic Bar Feeders

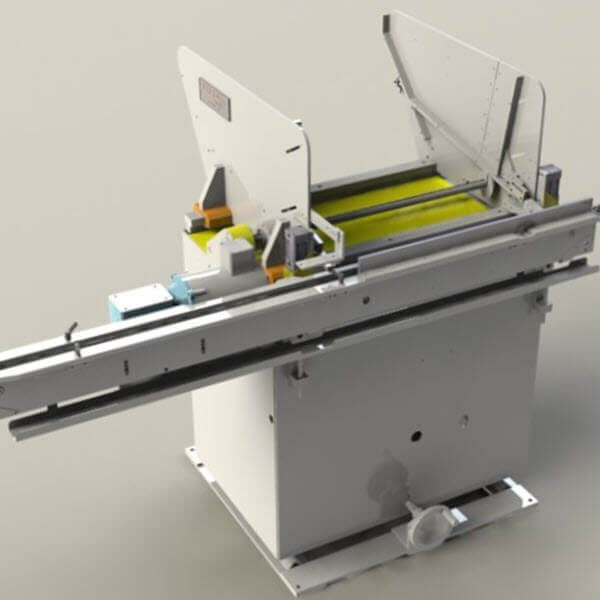

Bar feeder problems are especially troublesome when they materialize as part of a line leading into key secondary operations. Stoppages and delays at this point leave some of the most important applications of your entire operation without fresh parts to work with and effectively halt production. Feedall’s Magazine Style Automatic Bar Feeders are ideally suited to feed parts into a host of these applications, from centerless grinders, end finishers, induction heaters, robot-loaded cells, and many more.

With their magazine capacity, these loaders minimize handloading bars and shafts into secondary operations freeing up personnel to oversee more cells or address other production components. Feedall’s Model 1700-D comes with hand wheels for quick adjustments for length changes and equally simple adjustments for diameter changes of the parts being fed. No electrical connection is required for the automatic, air-operated escapement device. Conveyor systems can be incorporated into the design easily.

View the 1700-D Model | See It In Action

The 1700 comes with additional versatility. It can handle part diameters from ¼ to 2 inches and lengths between 2 and 28 inches. But heavy-duty magazines can be implemented for bars and shafts up to 4 inches in diameter and 12 feet in length. A bench-mounted version is also available.

If you require feeding of smaller diameter (or shorter length) bars and similar parts, Feedall has options (Model 1750) to accommodate — and avoid the bar feeder problems associated with other methods. Built from a standard, proven design, all of our automatic bar feeders come imbued with versatility and the capability to be tailored for nearly any feeding challenge.

Auto Loaded Bar Feeders

For larger bars and billets, and perhaps too big to take full advantage of magazine-style loading, Feedall’s Auto Loaded Bar Feeders serve as an ideal solution. By using an elevator belt, this model of bar feeder orients parts naturally and prevents misoriented parts from being recirculated — while also eliminating the need for hand-loading.

Parts exit the feeder one at a time to the next production phase due to an automatic, air-operated part qualifying device and an automatic, air-operated escapement device.

View the Model 2236 | See It In Action

Lastly, for even thicker and heavier billets and bars — up to 6” in diameter — our heavy-duty billet feeders offer more capability. These heavy-duty feeders also prevent parts from falling back into the queue and do so without the use of vibration or gravity to manage the part orientation.

Find what you need: Get suggestions on potential automation solutions with our Find-A-Feedall page. Simply enter the part and the application, and view the results.

Eliminate Bar Feeder Problems with Feedall

At Feedall, we do much more than provide one part or system to your manufacturing processes. We solve specific problems you encounter in your production environment with automation systems that seamlessly integrate into your existing setup.

We act as a true partner, working with you to learn about the parts you produce, the size and scope of your facility, and then fulfilling your requirements with equipment designed to maximize efficiency and production. We provide custom solutions and then offer value-adding tooling to further tailor the equipment for your applications.

Most importantly, each piece of customized equipment is also designed to last while also aiding your reach in achieving production goals. With support services, part availability, and a best-in-class repair program, our equipment continues to deliver the same high performance year after year and is capable of providing decades of service.

From bulk material handling equipment to essential conveying systems and more, Feedall helps you get the most out of your manufacturing operations. In a rapidly-changing and challenging world, we’re the partner that provides a competitive advantage through automation.

Connect with us today to discuss how our automation solutions can optimize your production facility.