CASE STUDY

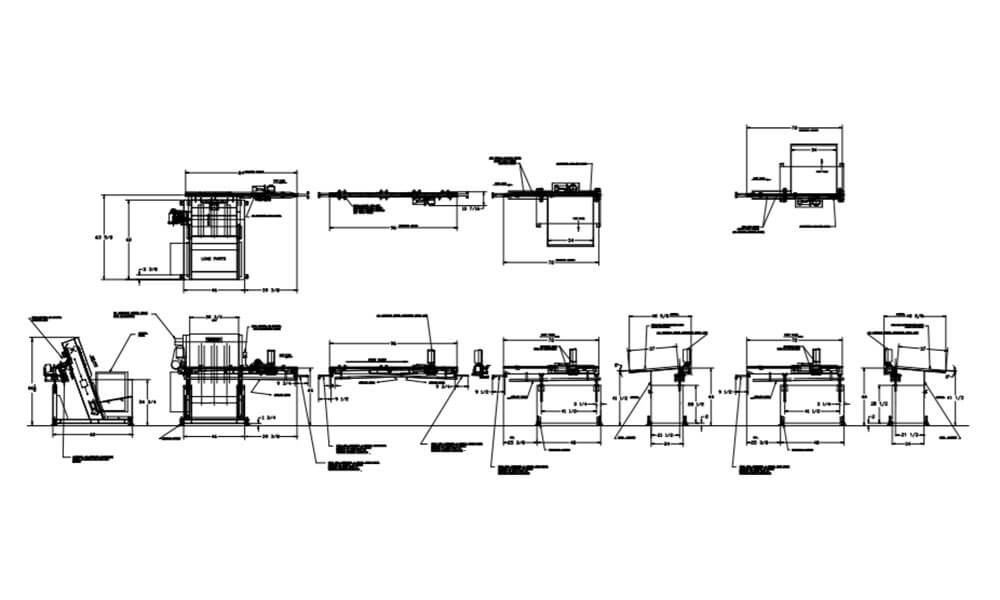

16991: PROJECT FEEDING STEERING RACKS INTO CENTERLESS GRINDER

Feedall Model

Model 1650-2PB-96 Intermediate Conveyor

APPLICATION

Feed from an automatic or random loaded, floor mounted hopper. The Steering Racks will then be elevated from the hopper and discharged rolling into an accumulation chute, where they will be escaped one at a time onto a rear mounted, cross-feed conveyor. The conveyor will transfer the parts in a continuous stream to the workrest of a CINCINNATI Model 340-20 DE centerless grinder. Then a Model 1650 conveyor will transfer the parts between two CINCINNATI Model 340-20 DE centerless grinders. Then the next Model 1650 conveyor will transfer the parts from a CINCINNATI Model 340-20 DE centerless grinder onto a collection ramp.

WIDTH

36” Wide Elevating BeltDRIVE

1 HP/AC MotorPARTS FED (SIZE)

Steering Racks (25mm-30mmØ x 24”-33” Lg.)FEED RATE

5 Parts/Minute Menu

Menu