CASE STUDY

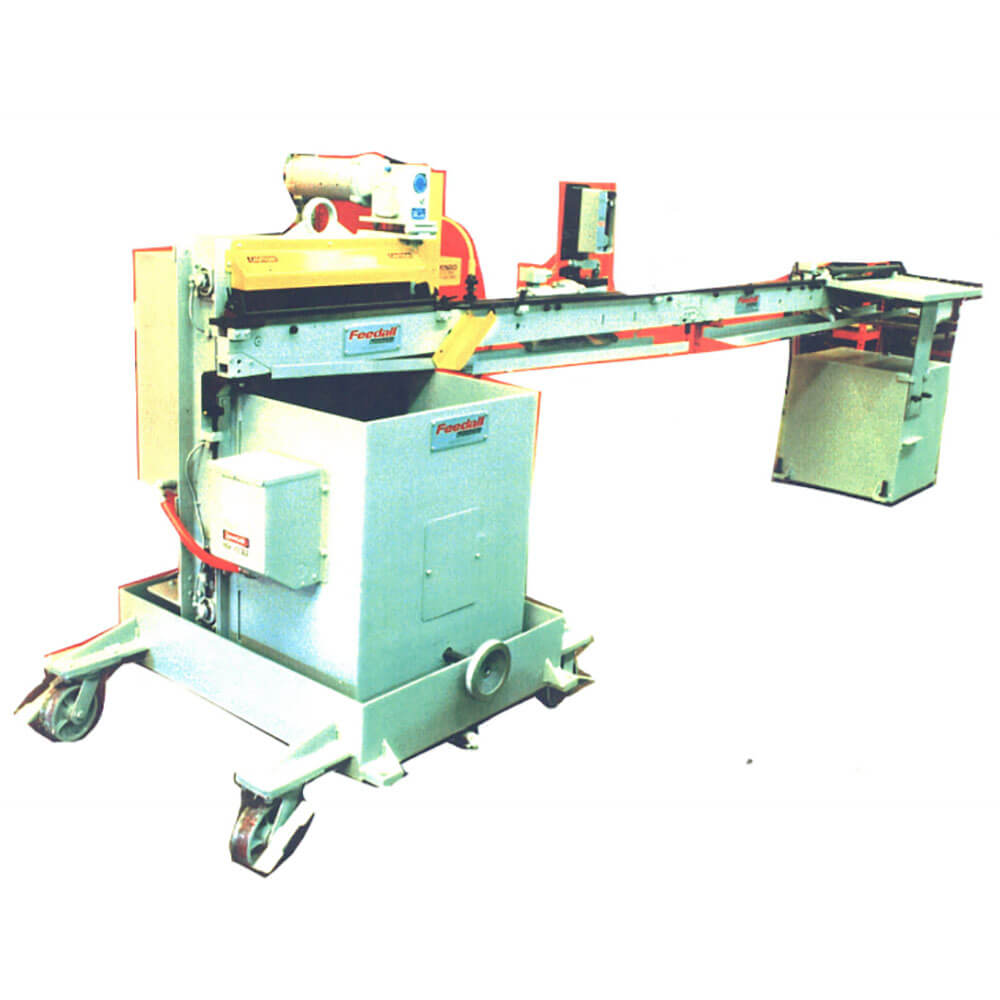

12815: PROJECT FEEDING TRANSMISSION SHAFTS INTO CENTERLESS GRINDER

Feedall Model

Model 2000

APPLICATION

Feed from a manually loaded floor hopper shafts .400 to .600″ DIA. to 23″ LG. The shafts will be elevated from the hopper then discharged rolling to the front mounted cross conveyor then fed end to end to a centerless grinder at 42″ above the floor at a rate of 75 to 150″ per minute. The shafts will then exit the grinder and be conveyed 72″ then discharged rolling to a collection tray for manual inspection and unloading.

24″ wide elevator belt, 2.1 CU. FT. Hopper and 72″ Conveyors.

DWG. PD 8574

WIDTH

24" wide elevator beltFEED RATE

75 to 150" per minute Menu

Menu