CASE STUDY

18108: PROJECT FEEDING STRUT SHAFTS INTO CENTERLESS GRINDER

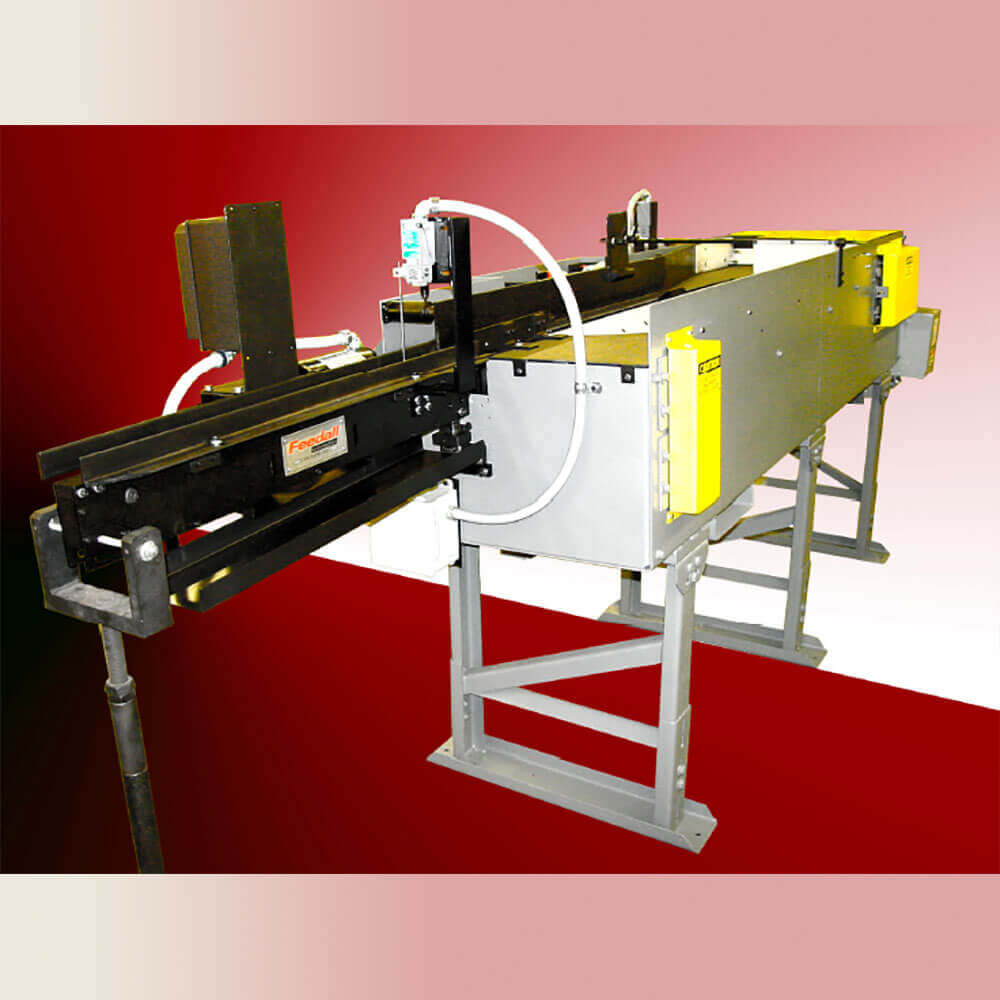

Feedall Model

Model 1500 Bi-Directional Orienting Conveyor

APPLICATION

Accept Steel Sleeves from customer’s manually loaded totes at random onto a Bi-

Directional Conveyor. Tubes will merge from the in-feed (load) lane onto the orienting

lane conveyor and discharged in a continuous, end-to-end stream to the workrest of a

Centerless Grinder.

WIDTH

7-1/2” Wide PVC - In-Feed (Load) Lane15” Wide PVC - Orienting Lane

1” Wide Silent Chain – Entrance Conveyor

DRIVE

1/2 HP/AC Motor w/Variable Frequency Controller – Bi-Directional Conveyor1/4 HP/AC Motor w/Variable Frequency Controller – Entrance Conveyor

PARTS FED (SIZE)

Steel Sleeves (0.50”-3.00”Ø x 0.75”-4.00” Lg.)FEED RATE

20 parts/minute (max.) Menu

Menu