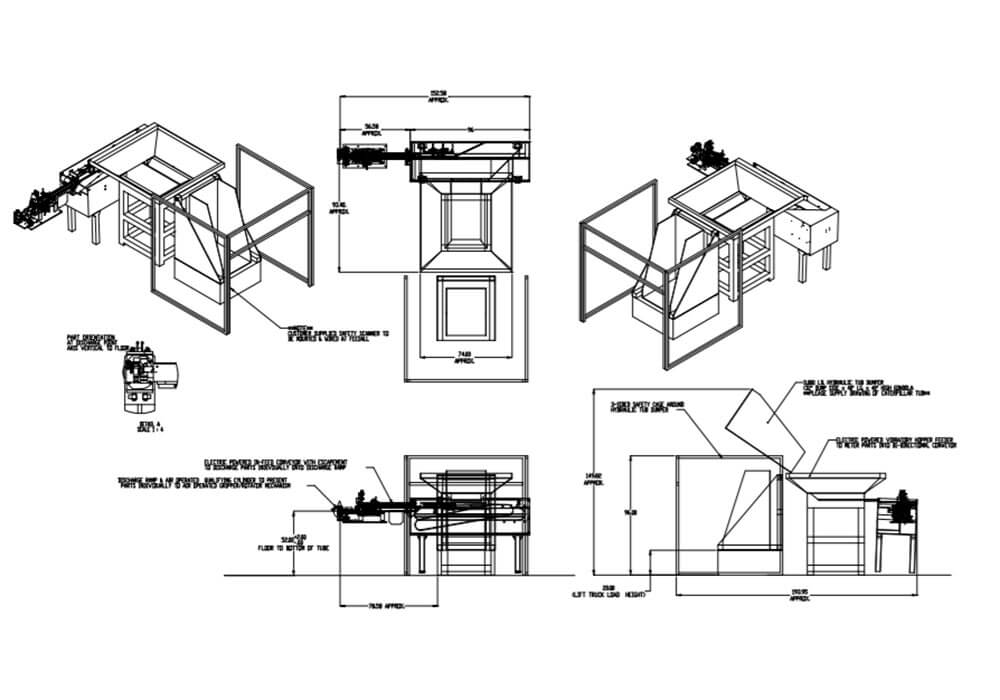

Application

Feed from a random loaded, floor mounted hopper. The Steel Tubular Slugs will be elevated from hopper via a tub dumper onto a vibratory hopper and spilled at random onto a bidirectional orienting conveyor. Slugs will merge from the in-feed conveyor lane onto the orienting conveyor lane and exit in a continuous, end-to-end stream to an automatic, air operated slug pusher device. Pusher device will load one slug at a time into an air-operated rotary actuator equipped with a pneumatic gripper. The rotary actuator will present the slug with the axis vertical with the bottom of the slug.

Width

24” Return Lane/18” Orienting Lane

Drive

1-1/2 HP/AC Motor

Parts Fed (Size)

Steel Tubes (17.27mm-74.62mmØ x 49.53mm-123.26mm Lg.)

Feed Rate

10 Parts/Minute