Application

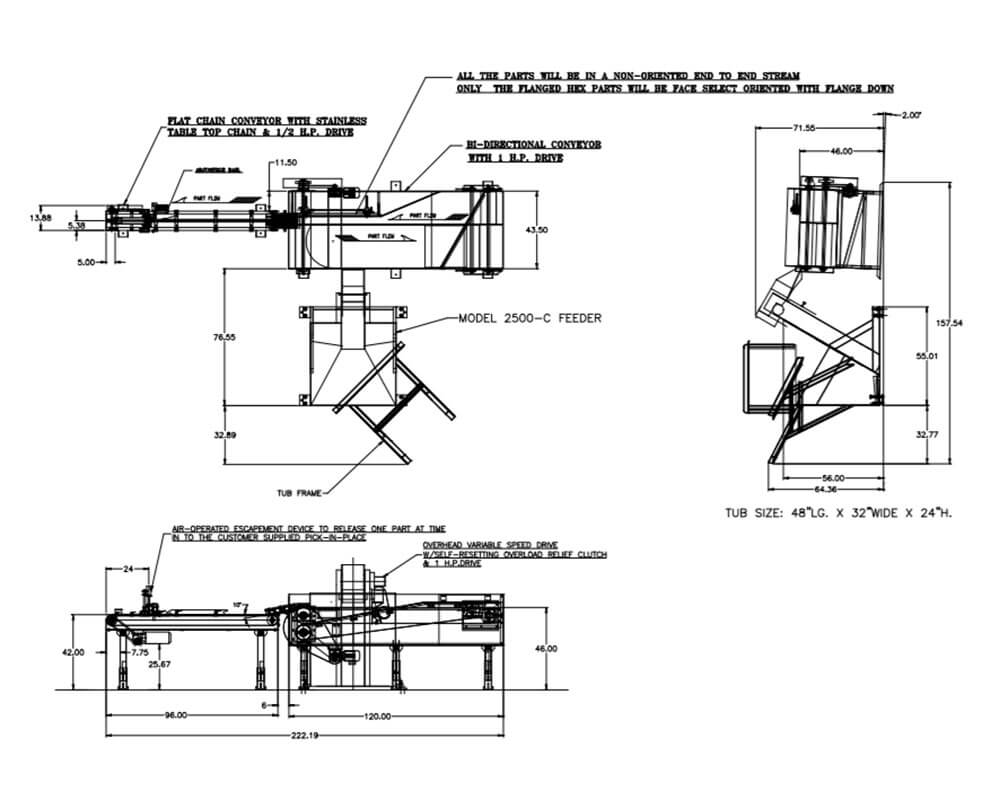

Feed from DROP BOTTOM TUB STAND. The parts will then be spilled randomly onto a bidirectional feed conveyor. The parts will merge from the in-feed conveyor portion onto the discharge conveyor. The parts will be escaped one at a time onto a customer supplied pick-nplace unit. All the parts will be in a non-oriented end-to-end stream released one at a time for part separation to allow for a customer supplied “vision system” to detect orientation for a customer supplied robot to pick up and load the part into a machining center.

Width

24” Return Lane/18” Orienting Lane

Drive

1-1/2 HP/AC Motor

Parts Fed (Size)

Pipe Fitting Forgings (Part Matrix)

Feed Rate

8-10 Parts/Minute