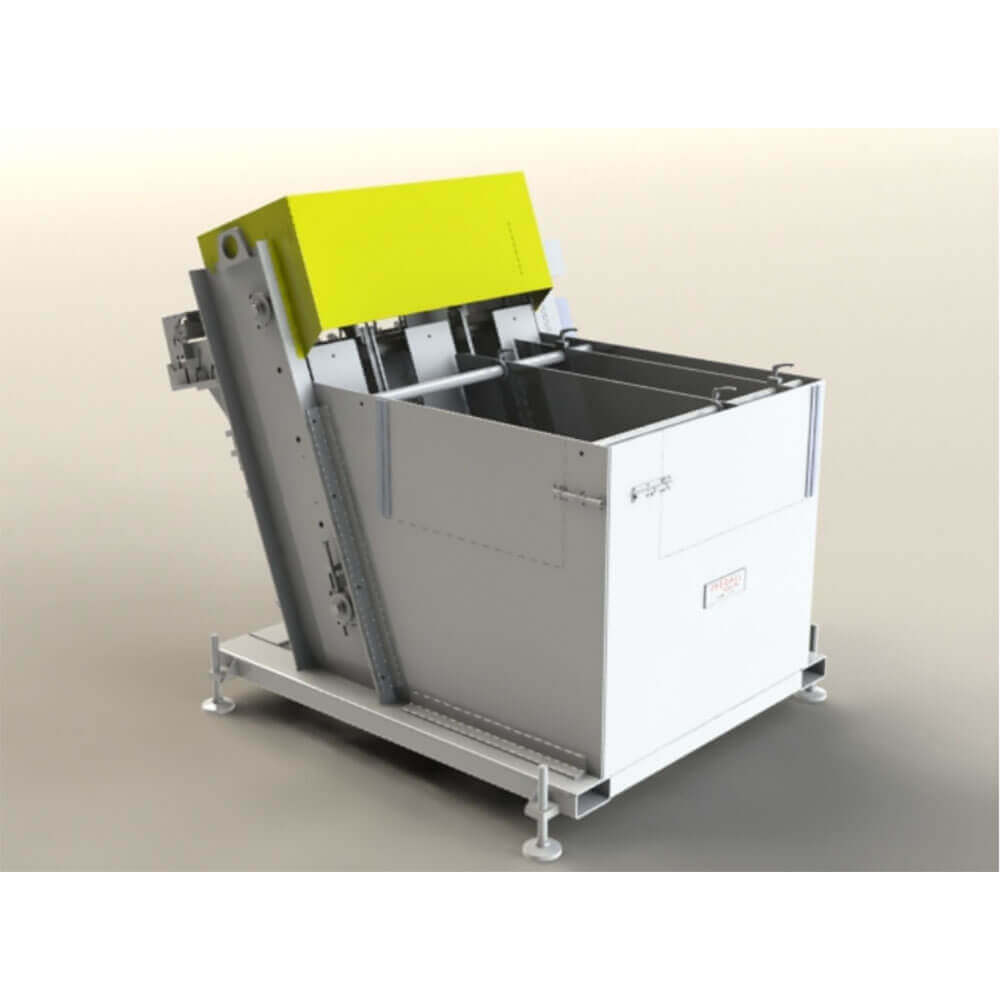

Application

Feed from a manually loaded, floor mounted hopper, Steel Tubes. The tubes will be elevated from the hopper via a cleated belt, carried over the top of the elevator and deposited onto a rear mounted, accumulation ramp in a continuous, diameter-to-diameter stream. An air-operated escapement device will load one part at a time onto the rear mounted, V-Nest for customer’s Robot pick-off.

Width

40” Wide Elevating Belt including Twin Strands of Elevator Chain w/Dual Attachments and Bolt-On Cleat/Pads

Drive

3/4 HP/AC with 230/460/3/60 Volt-Phase-Cycle w/Variable Speed Drive & Overload Relief Clutch

Parts Fed (Size)

Steering Racks (28.7mm-80mmØ x 213mm-1,000mm Lg.)

Feed Rate

4 Pars/Minute