Pointer

1695

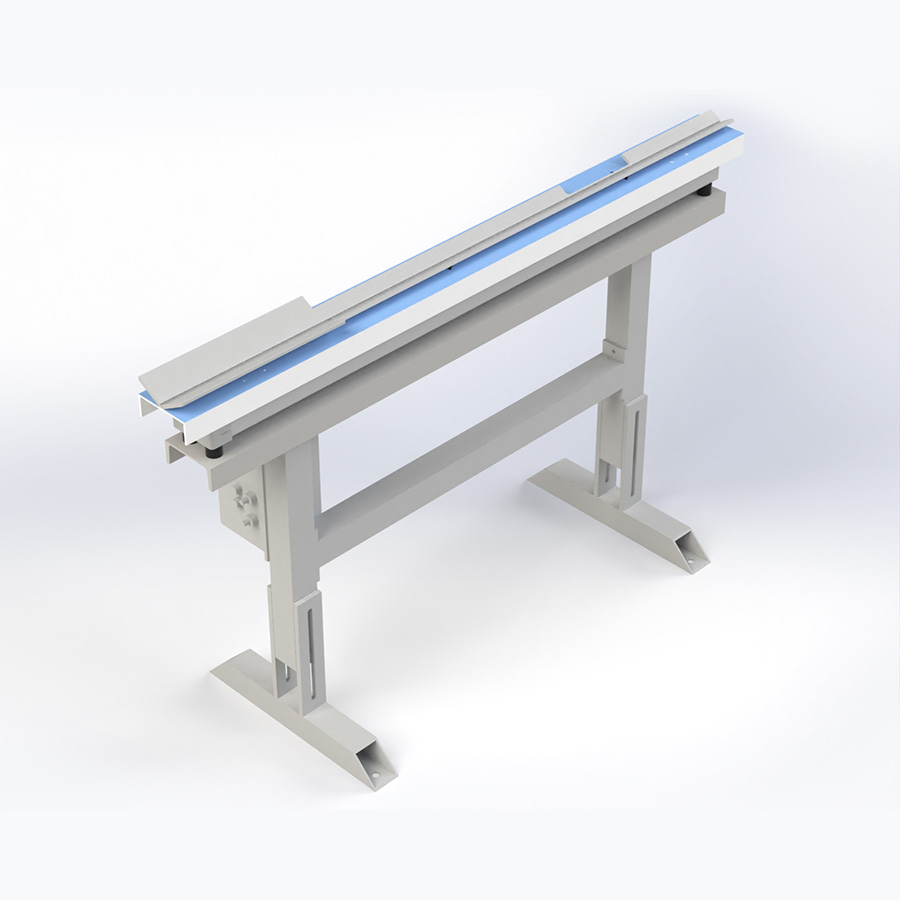

Achieve Better Control with V-Track Vibratory Conveyors

Named for the ‘V’ shape of the track or bed of the conveyor, V-track vibratory conveyors provide the same efficiency, versatility, and gentle handling of parts found with basic vibratory conveyors, but add better precision and part control. The V-track can be customized to fit the specific requirements of the parts it’s moving and the grooved nature of the track ensures those parts are positioned correctly for the next processing steps.

The Pointer 1695 is backed by the same high quality craftsmanship and value-adding customization options common to all of our automation equipment. Typically used for pins and shafts, our Pointer 1695 V-track vibratory conveyors are ideal for moving round parts of any size on their circumference.

Overview

Pointer 1695 V-track vibratory conveyors are specialized material handling equipment used in various industries for the controlled movement and orientation of parts and materials. These conveyors use a combination of vibration and track design to move items in a specific direction or pattern, which is particularly useful in automation and assembly lines. Since there are no rollers, conveyors can be placed end-to-end to provide whatever length you need. The gentle vibration is perfect for protecting the surface of the parts as they come out of a CNC machining center or similar process.

Versatility, flexibility, and durability are hallmarks of all of our automation equipment, and the Pointer 1695 is no exception. We work with you to understand our application needs and can provide options and custom solutions to create a perfect-fit conveyor solution. For instance, we can provide heavy duty versions to move solid, larger bars and accumulate hundreds of pounds of parts.

With no bulky motor to contend with, these conveyors are low profile and narrow enough to run right through your machining cell. This is aided by custom curved sections that can be designed per your requirements, include accumulation capacity and can include options such as purge gates and end stops.