Husky

2400 / 2500

Parts Feeders Designed for Larger, Random-Loaded Parts

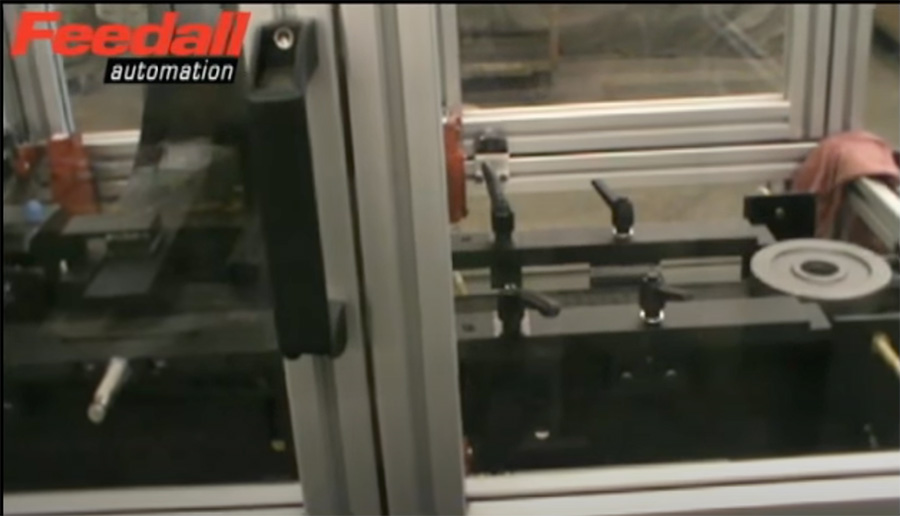

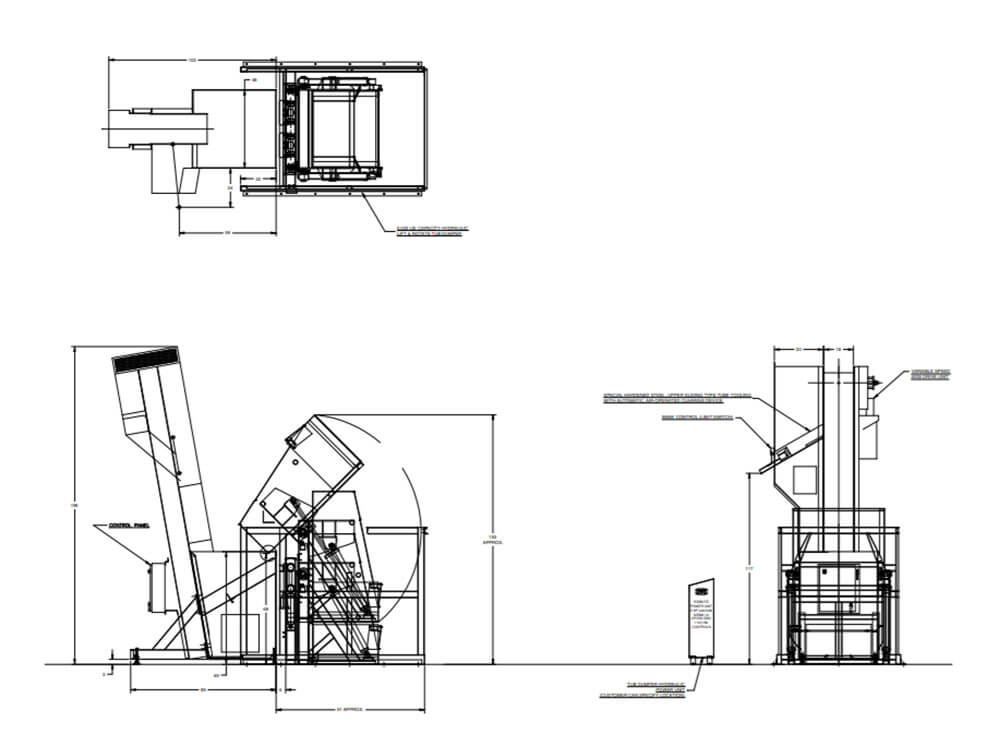

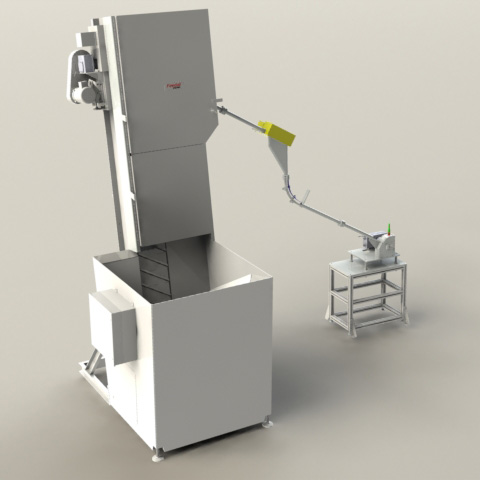

Feedall Automation offers a comprehensive range of orienting, hopper-fed parts feeders built with the necessary strength and resiliency to handle larger, longer, and heavier parts. These selections from our Husky line are designed to automatically feed random-loaded sliding, rolling-headed, or hanging parts with diameter ranges with a 2:1 ratio. Parts are gravity fed into these elevator-style feeders, with various orienting components designed to properly align them and provide a continuous flow of product.

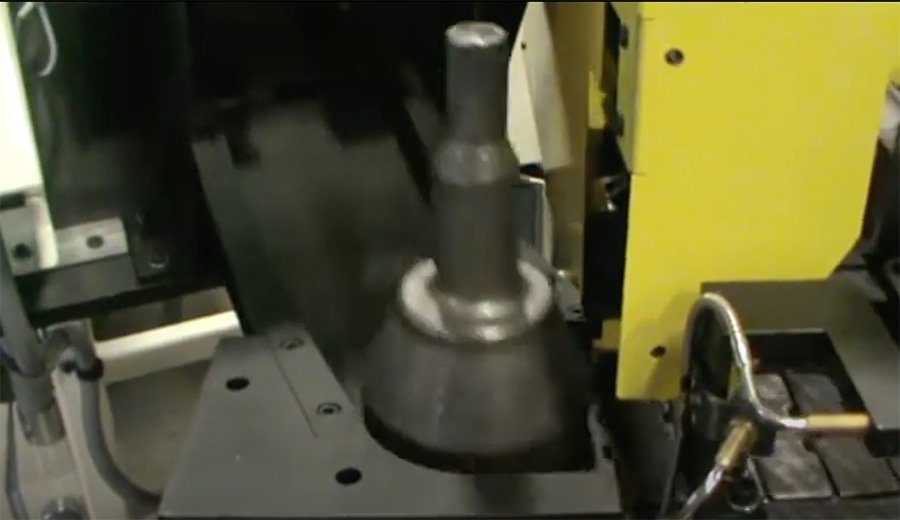

Our random-loaded parts feeders are ideal to set up robot-assisted CNC machining cells, robotic pick-and-place cells, and a host of industrial manufacturing equipment and specialty machines, such as grinder, presses, forging equipment, and more.

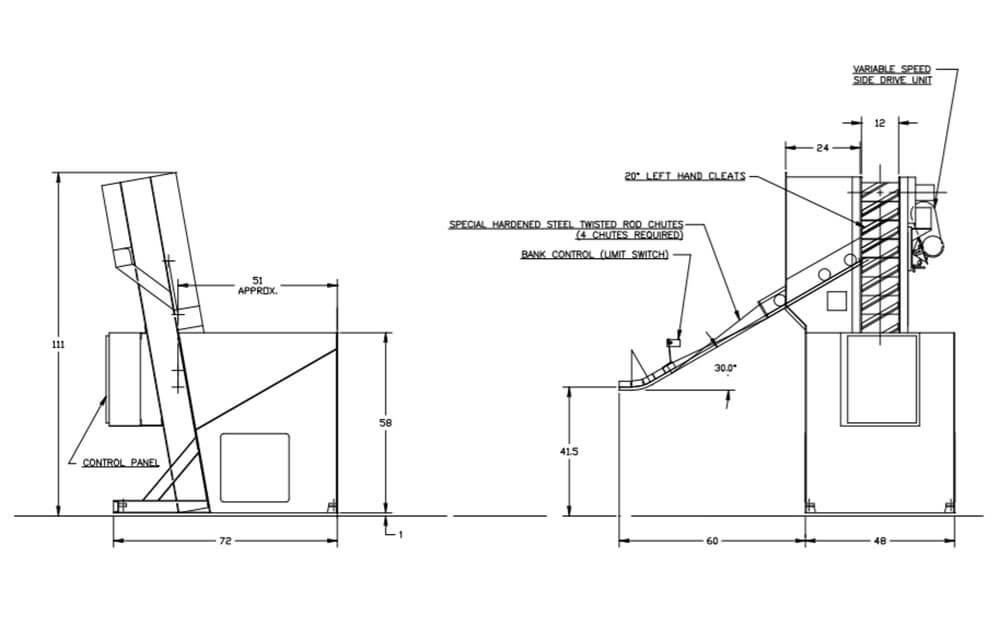

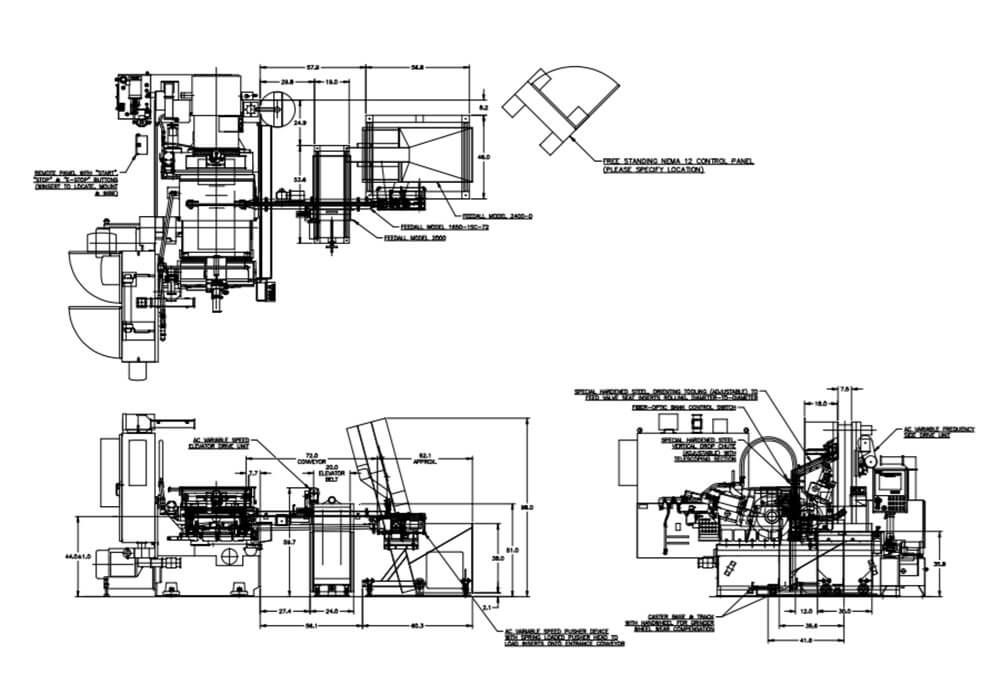

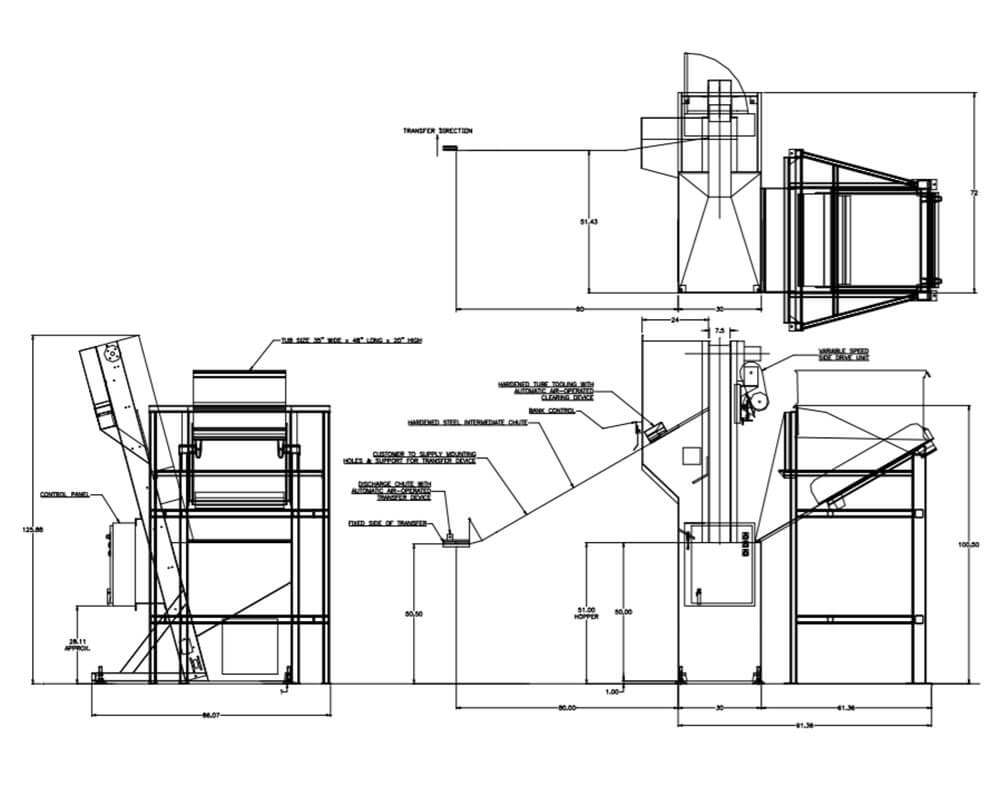

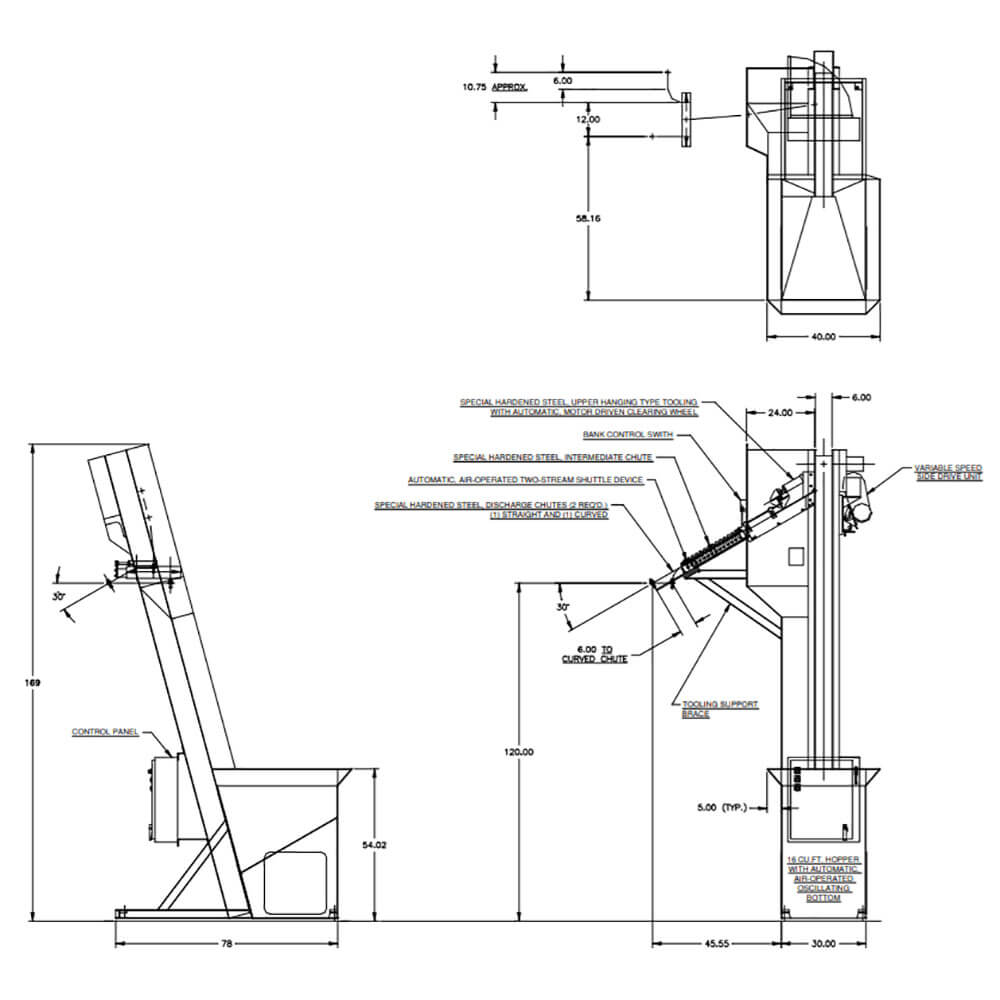

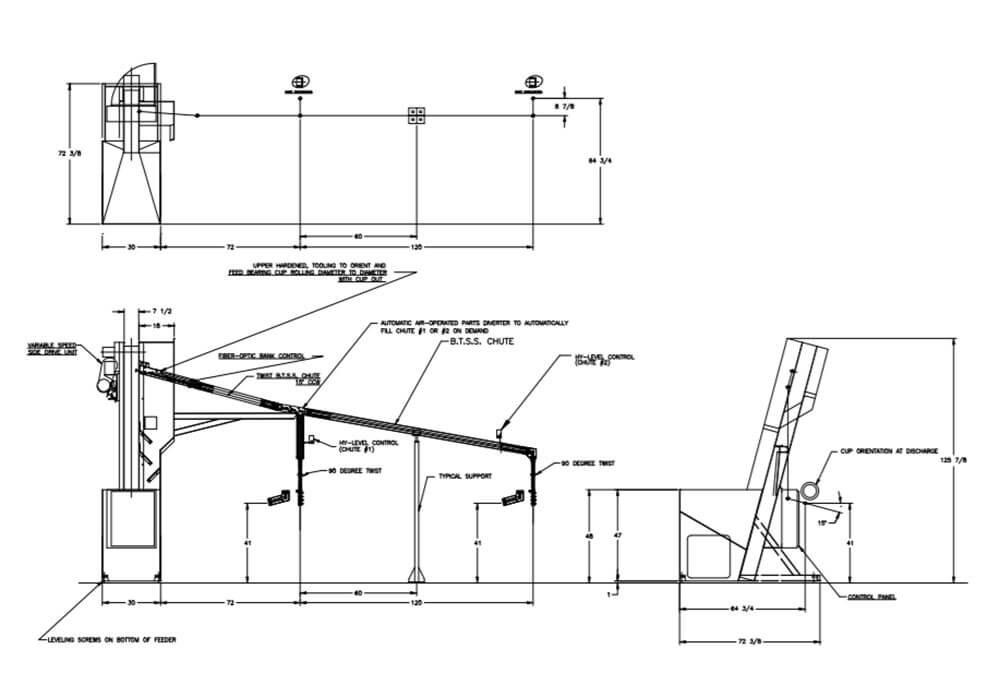

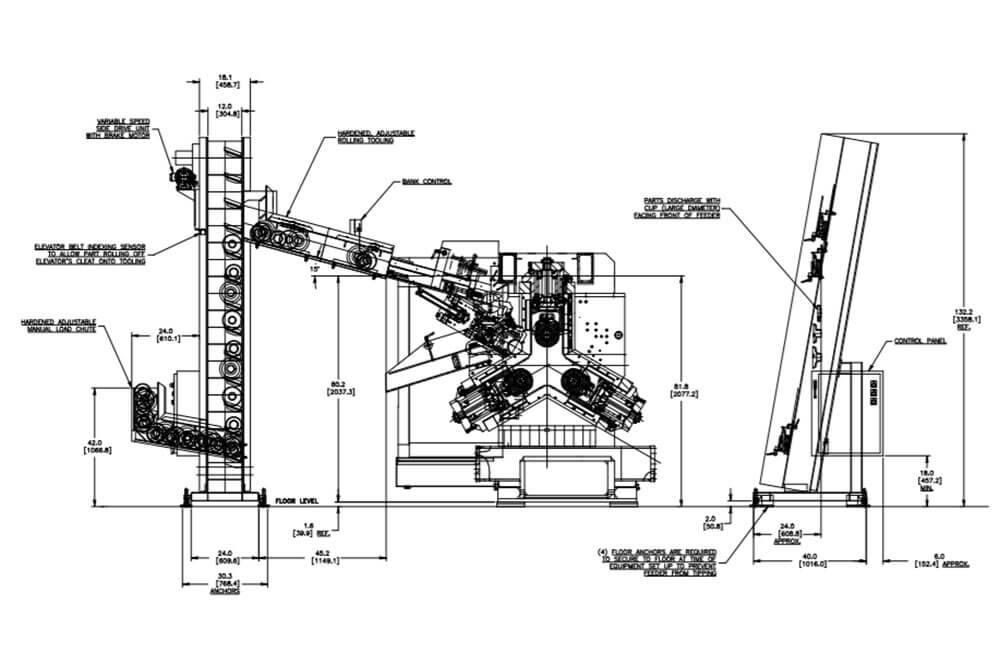

Our Husky random-loaded parts feeders come in two primary models. The 2400 Model is the standard lighter duty variety, with a hopper capacity of 6 cubic feet and a 6 inches wide elevating belt (which can be upgraded to 7-1/2 inches for larger parts or higher feeding rates). Its floor space footprint is 30 inches by 60 inches and typically handles parts such as rods, bushings, ball studs, trunnions, and inner and outer bearing braces.

The 2500 Model is larger and more capable in handling larger or heavier parts from a random-loaded hopper. Its hopper can have an expanded capacity of up to 20 cubic feet, a wider elevating belt (up to 12 inches), and requires more floor space (48 inches by 64 inches). Larger models are also available.

All of the random-loaded parts feeders come with standard Feedall features to maximize productivity:

- Proper part delivery — Parts are oriented and placed in a chute, with right- or left-hand takeoff, or two-track delivery

- Custom elevators — Cleat height and spacing is designed-to-size for the parts being fed

- Durability — Chutes, wear strips, cleats, and tooling are hardened for extended service

- Adjustable elevation — Height of the elevator may be varied to suit the application

- Designed accessories — Automatic bank controls, air operating devices, diverters, and other options may be added with new tooling designs

- Tooling plate — Controls the rate at which parts fall into the hopper. Can also be equipped with polyurethane-lined baffles

- Speed Control — Feed rate is determined by the speed of the elevating conveyor, which has a self-contained mechanical variable speed drive or infinite speed D.C. drive optional. Handwheel adjustment is easily accessible