Part Orientation

Solutions

Turn to Custom Part Escapements for Improved Part Orientation

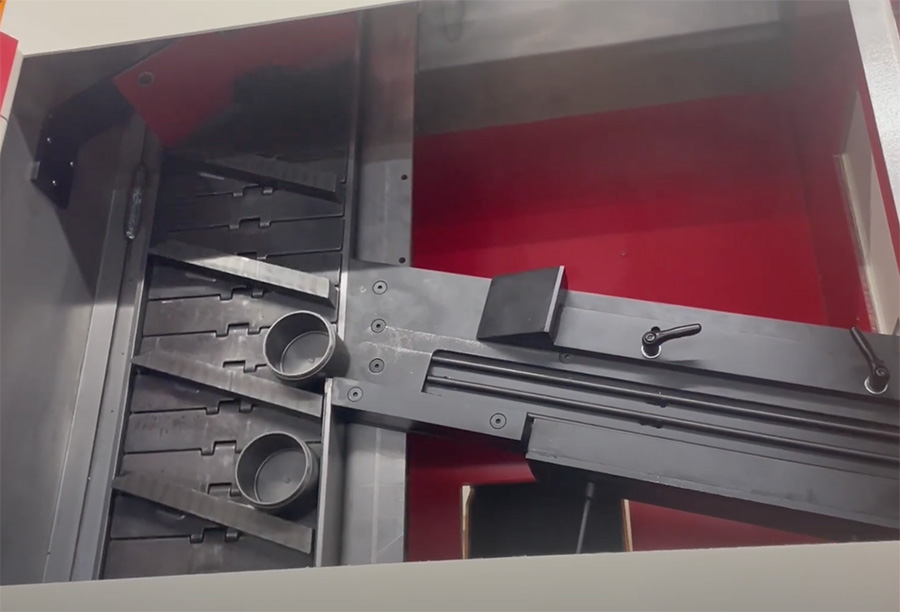

Custom part escapements in industrial automation are specialized mechanisms designed to precisely control the release of individual parts from a feeder into the next phase of a manufacturing process. These devices are crucial for operations where specific orientation, timing, and placement of parts are necessary for subsequent automated actions, such as assembly, inspection, further processing, presenting parts for robot-assisted CNC machining, and more.

Overview

Feedall Automation has an extensive list of custom escapements with options for virtually every piece of automation equipment we offer. It’s important to discuss your specific needs and requirements with our team of automation experts to learn which escapements will fit your needs most appropriately.

Our custom escarpments assist with part orientation to enable precision control in releasing parts one at a time from a bulk supply, are flexible enough to handle different parts and use cases, and easy to integrate with other automation components, such as conveyors, machine tending solutions, and more. Below, we’ve detailed a few of our solutions in this area.

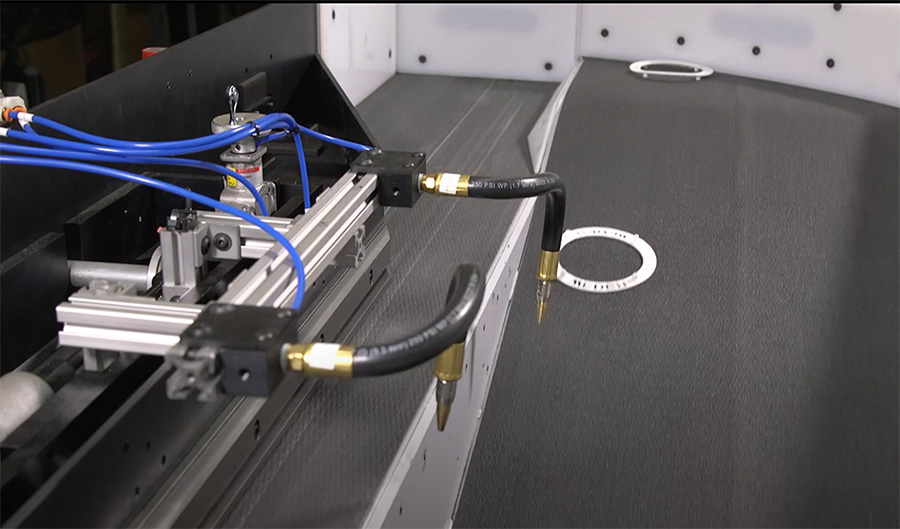

Part Gauges and Inspection Machinery

Feedall provides a complete line of solutions for part gauges and inspection machinery—including laser and Marposs gauges— by working with experts in dimensional gauging. We work closely together with our customers to design tailor-made applications according to their needs and requirements with integrated automatic production lines. We complement these solutions with made-to-order conveyor solutions.

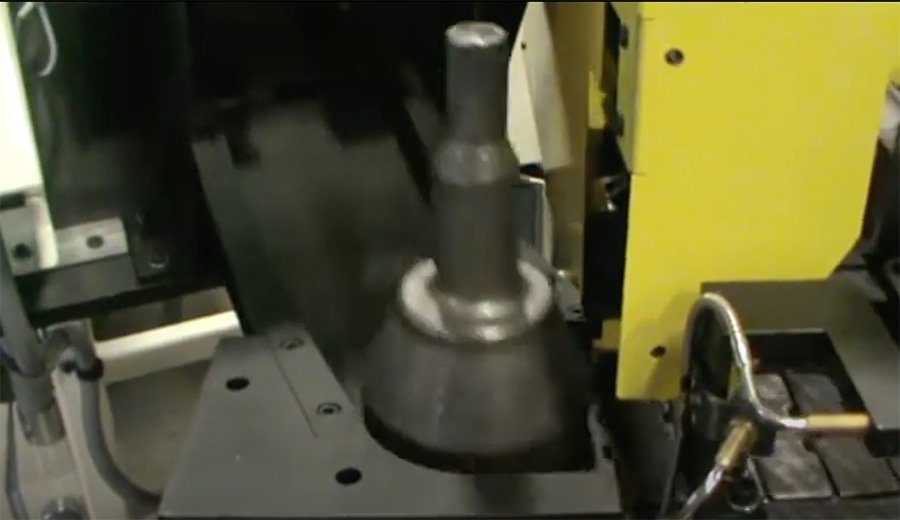

Part Pick and Place Automation

At Feedall, we recognize that one of the biggest applications for all of our feeding and conveyor equipment is presenting parts for part pick and place automation. We work closely together with our customers (both end-users and system integrators) to design tailor-made applications according to their needs and requirements for full system automated production lines. We custom manufacture all tooling for the proper EOAT (End of Arm Tooling) robotic tooling to grab any part configuration and improve part orientation seamlessly. If you are working with an application that needs to feed a robot, please reach out to us to understand how our equipment and tooling can help in your automation part pick and place unit needs.

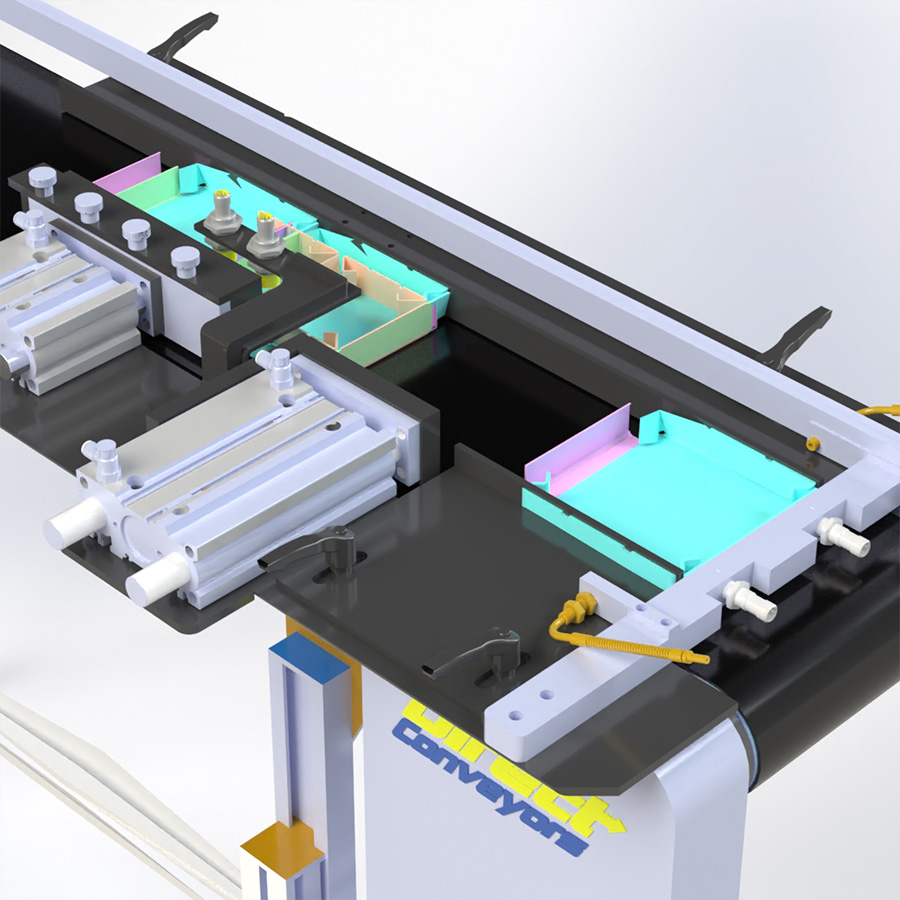

Part Singulation

In order for gantry systems and robotic arms to grab a part, it must have part-to-part separation. This “singulation” of parts is something that Feedall has mastered over its 75 plus years. Unique customized automation designs are sometimes required to escape a part for an accurate pick off. These part singulation designs are even more critical when the feed rate requirement is more than 30 parts per minute.