Ridgeback

1624

Gain More Robust Performance with Our Large Flex Feeder

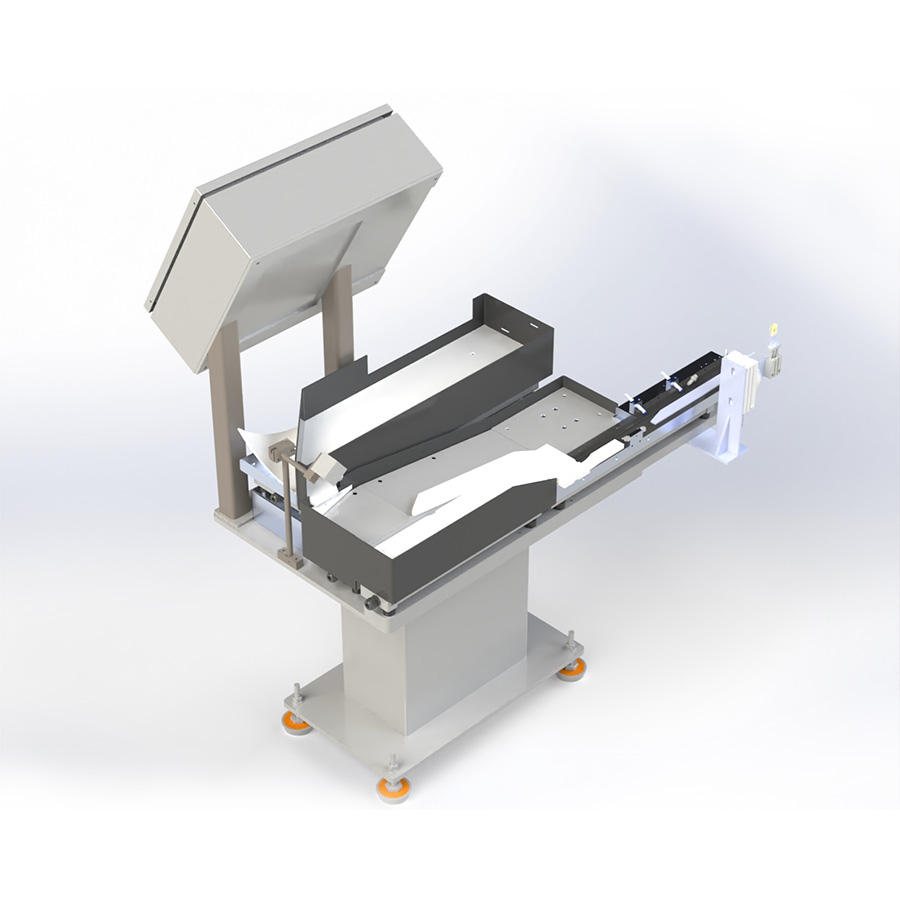

When seeking expanded capacity and capability from your flexible feeding solution, the Ridgeback 1624 widens the scope for what’s possible with a large flex feeder. Suited for larger parts and just as versatile as smaller models in handling varying part shapes, the 1624 has a more substantial base suitable for additions to further optimize parts feeding for vision-guided robot applications.

- No expensive 3D robot guided vision required

- No programming required

- Eliminates manual feeding while allowing fast product changeovers

- Smooth and quiet part handling

- Superior part separation and manipulation for robot pick efficiency

Overview

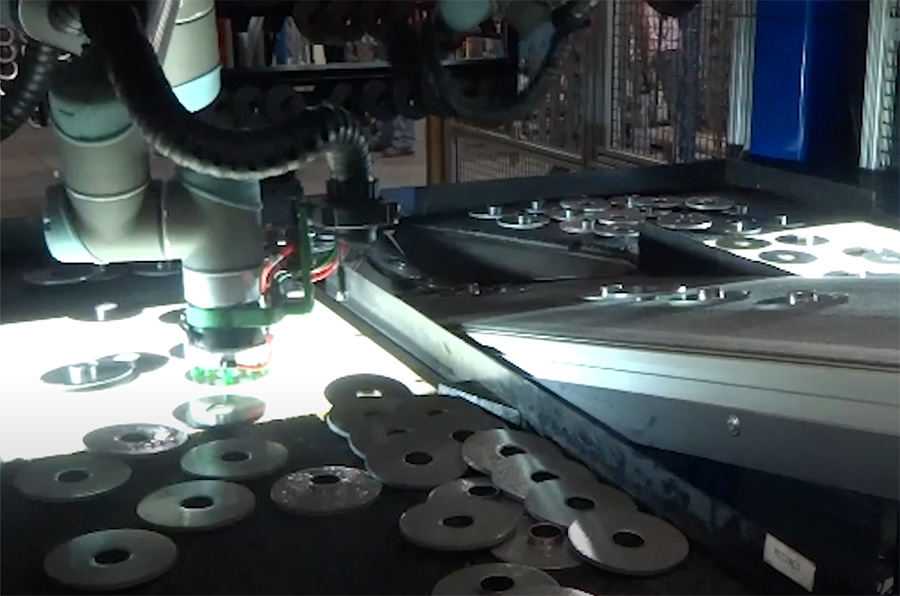

The Ridgeback 1624 features a vibratory recirculation table with dimensions of 16 inches by 24 inches picking area. As will all flex feeding systems, the vision system identifies a ‘pickable’ part in the zone and communicates the information to the associated robot to pick the part. The expanded recirculation area allows flexible feeding for parts up to 2.75 inches in diameter.

An integrated hopper with this large flex feeder can account for more than 100 pounds of parts and the custom designed controls allow ease of use; the Ridgeback 1624 can be running parts mere minutes after initial setup. Despite its more substantial size, it can be used as a table-top piece of automation equipment or mounted on a floor stand to position the pick area closer to the robot picking unit.

This large flex feeder can be outfitted with additional features, like dual-lane capabilities and our part-flipping Twist Track, in addition to our usual list of optimized features. To discover the perfect mix of features and options, connect with our automation experts and engineering team.

- Optional Airbox for separating tangle parts

- Optional backlight for the picking zone

- Option gentle part flipping fixtures

- In-line or perpendicular hopper placement

- Modified hopper size and capacity