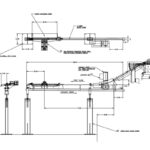

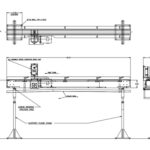

Thru Feed Conveyors

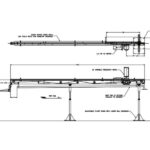

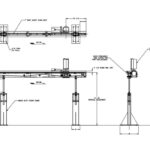

Model 1650

Grinder Infeed Conveyor

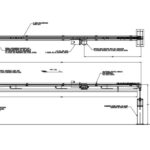

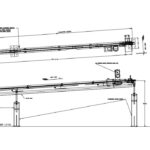

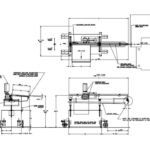

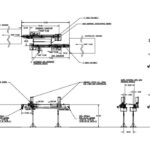

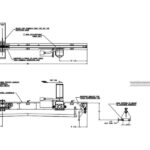

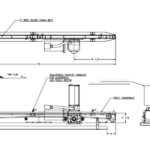

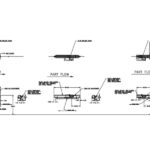

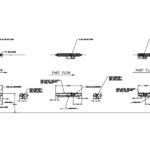

Feedall Thru Feed Conveyors: The Feedall line of thru feed conveyors offer infeed and exit capabilities for complete automated shaft feed systems. Model 1650 features conveyor lengths of 62 1/2” and 72”, with a diameter range of 1/4” to 2”. Our variable speed drive operates up to 50 FPM with a 1” silent chain or non-marking belt. Count on Feedall for all your automatic parts feeders.

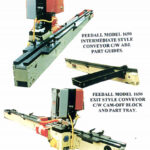

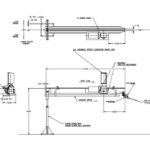

Applications: The Feedall line of Thru Feed Conveyors offers entrance, intermediate and exit capabilities for a wide variety of machine tools and processes including centerless grinding, thread rolling, belt finishing, heat treating, and assembly. Special design considerations allow these conveyors to operate in harsh environments (oily, chips, grinder swarf, etc.).

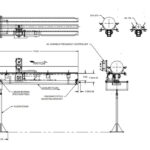

Feedall Model 1650 Thru Feed Conveyor with Roller Chain is designed and built around two specific applications 1) forging and 2) induction hardening; however it can be utilized in many other applications. Forging applications are extremely rough and abrasive as are the billets that need to be conveyed, and Feedall’s roller chain conveyors are designed to handle these tough conditions.

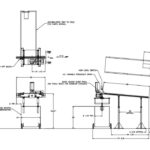

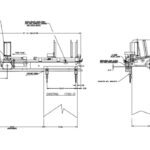

Optional Features of Model 1650

- Conveyor lengths from 36” to 144”

- Mechanical part cam off block with short discharge ramp

- Powered overhead driven wheel

- Floor stands and support bases

- Ball bushing mounts (floor stand and base)

- 2” wide silent chain or belt

- Custom designed applications

- Air operated side transfer devices

- Gap style conveyor for inline gauging

- Remote mounting of DC Controller custom designed to suit

Menu

Menu