CASE STUDY

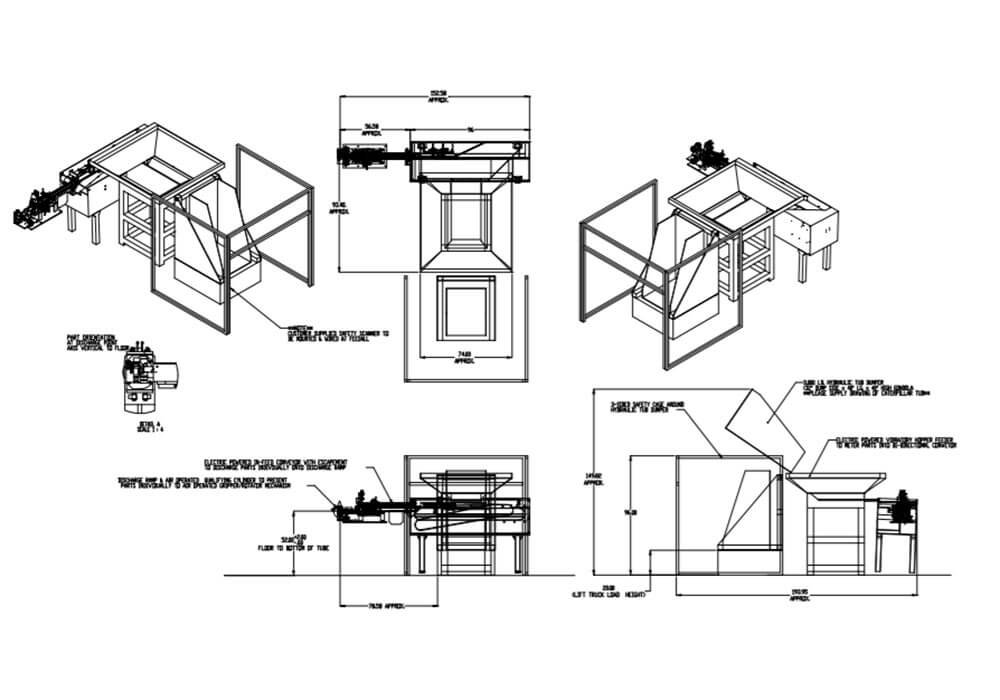

17389: PROJECT FEEDING STEEL TUBES INTO PRESS

Feedall Model

Model 1500 Bi-Directional Orienting Conveyor w/3,000# Vibratory Metering Hopper, TC-38-84-3,000# Hydraulic Tub Dumper & GLH-3.5-4 Exit Conveyor

APPLICATION

Feed from a random loaded, floor mounted hopper. The Steel Tubular Slugs will be elevated from hopper via a tub dumper onto a vibratory hopper and spilled at random onto a bidirectional orienting conveyor. Slugs will merge from the in-feed conveyor lane onto the orienting conveyor lane and exit in a continuous, end-to-end stream to an automatic, air operated slug pusher device. Pusher device will load one slug at a time into an air-operated rotary actuator equipped with a pneumatic gripper. The rotary actuator will present the slug with the axis vertical with the bottom of the slug.

WIDTH

24” Return Lane/18” Orienting LaneDRIVE

1-1/2 HP/AC MotorPARTS FED (SIZE)

Steel Tubes (17.27mm-74.62mmØ x 49.53mm-123.26mm Lg.)FEED RATE

10 Parts/Minute Menu

Menu