CASE STUDY

16819: PROJECT FEEDING DIFFERENTIAL PINION DRIVE SHAFTS INTO PRESS

Feedall Model

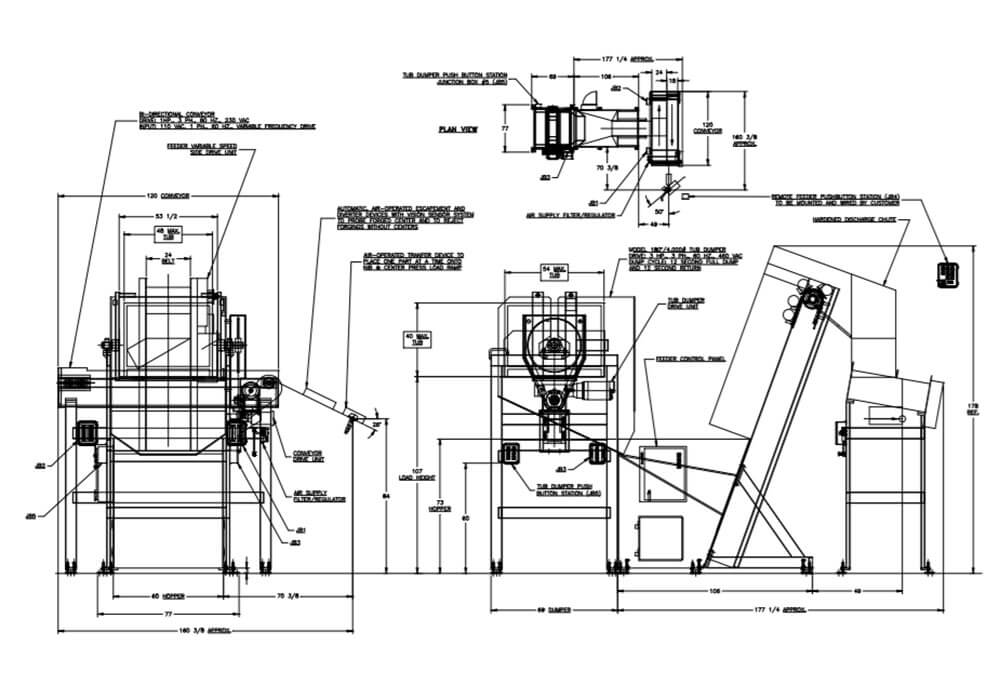

Model 1500 Bi-Directional Orienting Conveyor w/Model 2700-HD Elevating Bulk Hopper Feeder & 180º Roll-Over Tub Dumper

APPLICATION

Feed from a random loaded, floor mounted hopper. Pinion Shaft Forgings will be elevated from hopper via a cleated belt and discharged onto a bi-directional orienting belt conveyor. This conveyor will orient forgings and discharge them with stems down into adjustable hanging rails to an air-operated escapement device. This device will escape forgings one at a time into a probe check station that will divert forgings without forged center into a reject chute. The forgings with forged centers will feed into discharge rails to an air-operated transfer device that will feed the existing transfer system on the Nib & Center Machine. The system will also include a vision inspection system to check for presence of the center after the nib process and stop press if presence is not detected.

WIDTH

24” Wide Elevating BeltDRIVE

3 HP/AC MotorPARTS FED (SIZE)

Differential Pinion Drive Shaft Forgings (2.30”-6.00”Ø x 7.00”-16.00” Lg.)FEED RATE

10 Parts/Minute Menu

Menu