CASE STUDY

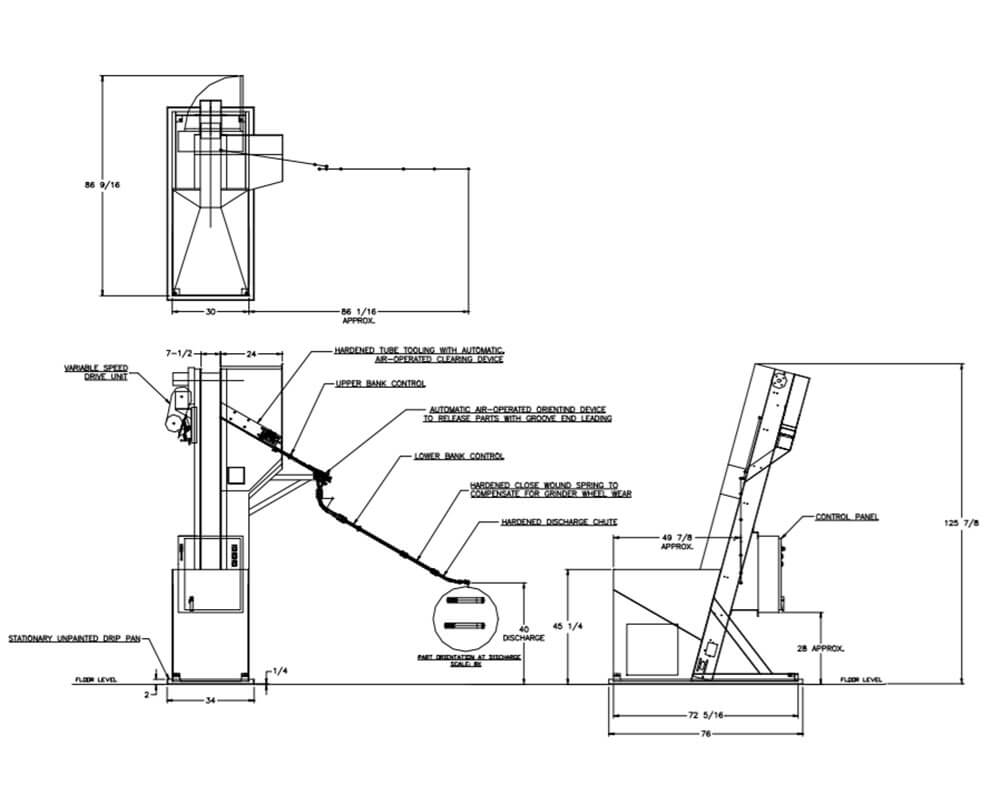

16675: PROJECT FEEDING STEEL SHAFTS INTO CENTERLESS GRINDER

Feedall Model

Model 2400-D Elevating Hopper Feeder

APPLICATION

Feed from a random loaded, floor mounted hopper. The Shafts will be elevated from the hopper via a cleated belt and discharged in a continuous stream at 30° into an air-operated orienting device. Then the parts will be discharged into a Centerless Grinder.

WIDTH

7-1/2” Wide Table-Top ChainDRIVE

1/2 HP/AC MotorPARTS FED (SIZE)

Steel Shafts (0.242”Ø x 1.763”-1.913” Lg.)FEED RATE

12-15 Parts/Minute Menu

Menu