CASE STUDY

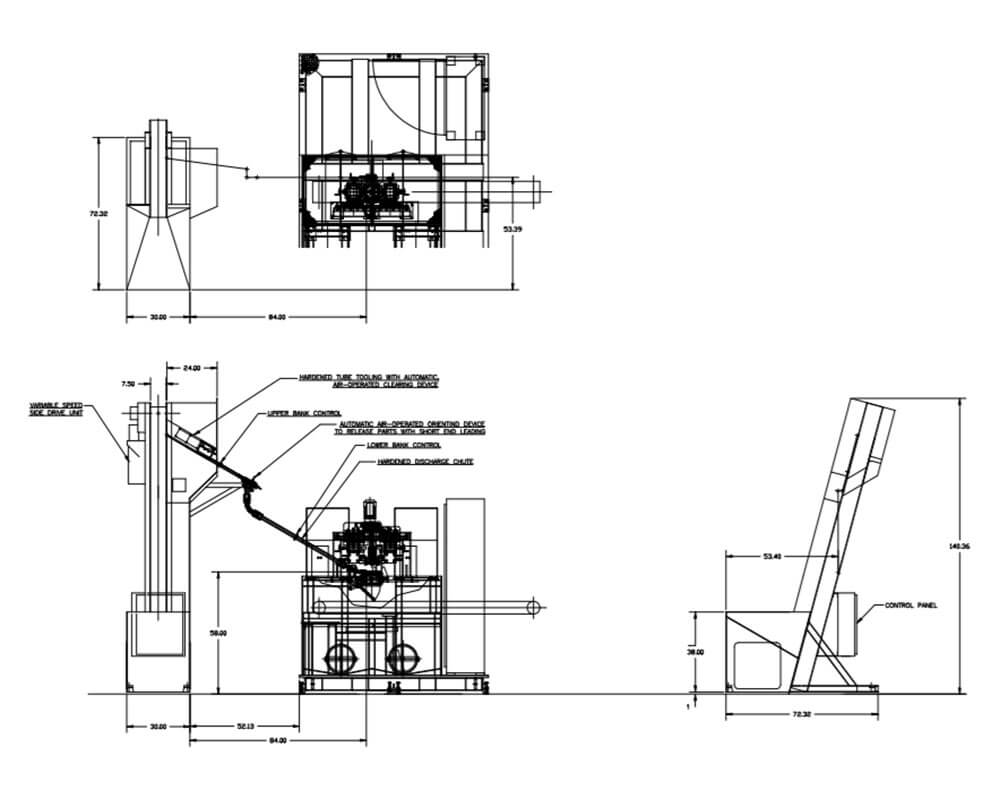

15805: PROJECT FEEDING CLOSURE PINION SHAFTS INTO INDUCTION HARDENER

Feedall Model

Model 2400-D Elevating Hopper Feeder

APPLICATION

Feed from a random loaded, floor mounted hopper. The Closure Pionion Shafts will be elevated out of the hopper and discharged sliding end to end into a shifting mask orienting device. The orienter will release the parts with the long or short end leading into a part nest for Robot pick-up.

WIDTH

7-1/2” Wide Table-Top ChainDRIVE

1/2 HP/AC MotorPARTS FED (SIZE)

Closure Pinion ShaftsFEED RATE

1 Part/5.5 Seconds (≈11 Parts/Minute) Menu

Menu