CASE STUDY

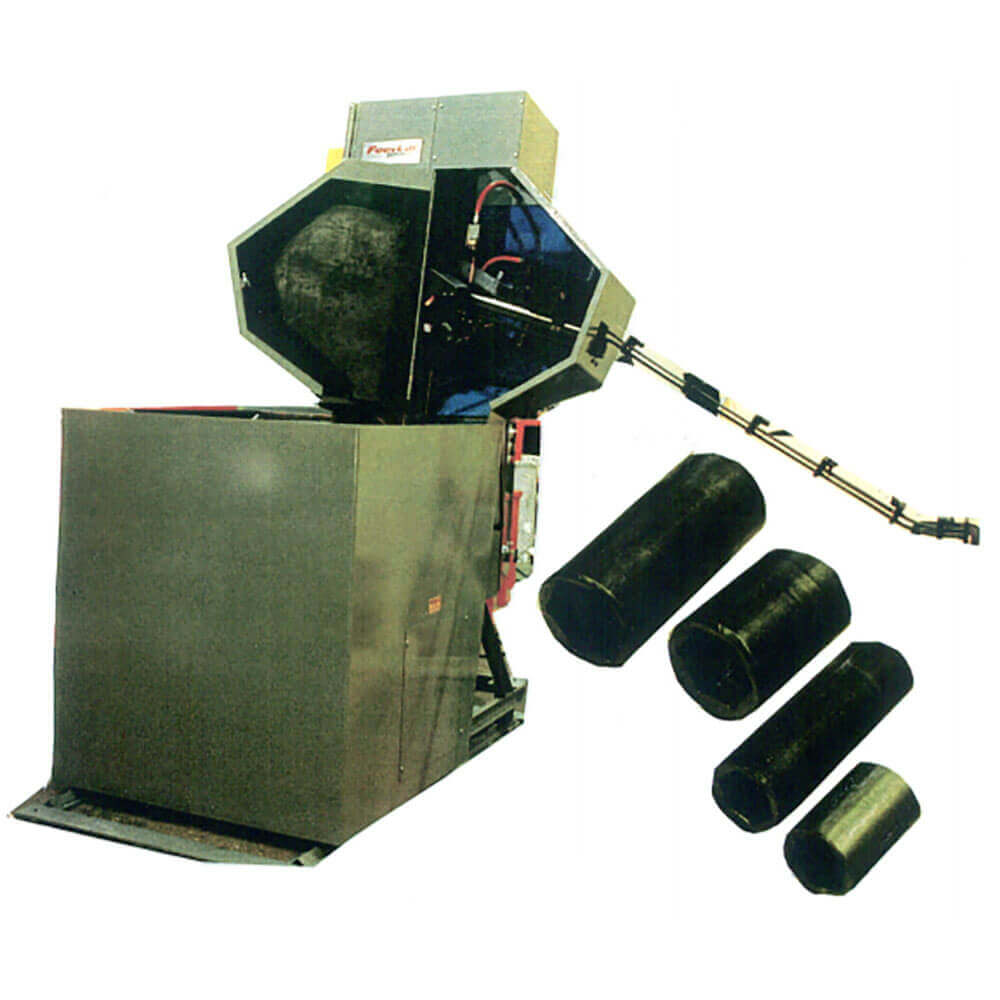

13610: PROJECT FEEDING SOCKETS INTO CENTERLESS GRINDER

Feedall Model

Model 2500 C

APPLICATION

Feed from a random loaded floor hopper socket wrenches .750″ to 1.500″ diameter in various lengths. The sockets are elevated from the hopper then discharged sliding through a feed roll with a clearing wheel to remove any misoriented sockets. The sockets will exit the feed rolls and slide through an adjustable rod type chute to a centerless grinder at 42″ above the floor at a feed rate of 75 to 200″ per minute.

12″ wide elevator belt, 12 cubic foot hopper.

DWG. P-7095 R 2

WIDTH

12" wide elevator belt, 12 cubic foot hopperFEED RATE

75 to 200" per minute Menu

Menu