CASE STUDY

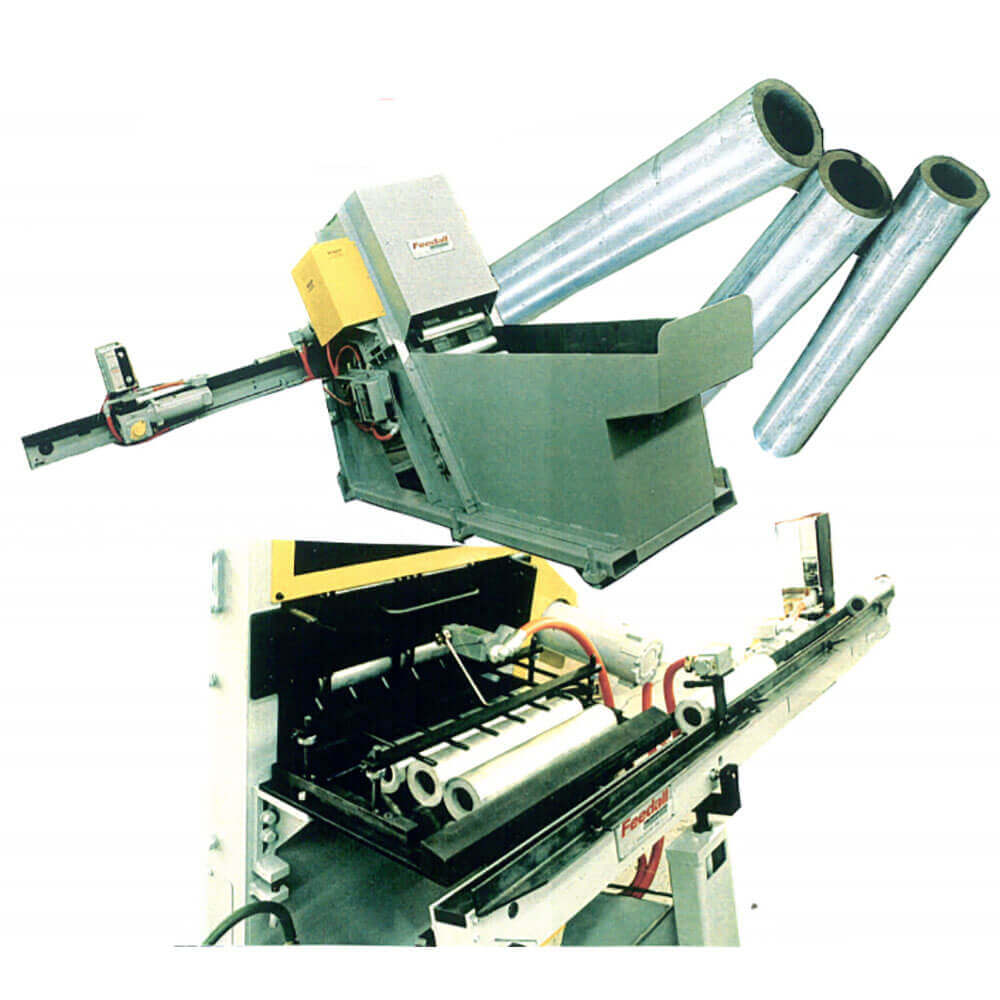

13505: PROJECT FEEDING ALUMINUM TUBES INTO FRICTION WELDER

Feedall Model

Model 2220

APPLICATION

Feed from floor hopper aluminum tubes 2″ to 3″ DIA. by 12″ to 20″ LG. Tubes will be loaded with bundle gripper in bundles of 60 to 150 tubes. Tubes are elevated and discharged rolling to the rear into a magazine, then escaped one at a time to a cross conveyor and fed to a friction welder at a rate of 2 to 8 per minute at a height of 37″ above the floor.

DWG. PD 9218 – R1

FEED RATE

2 to 8 per minute Menu

Menu