CASE STUDY

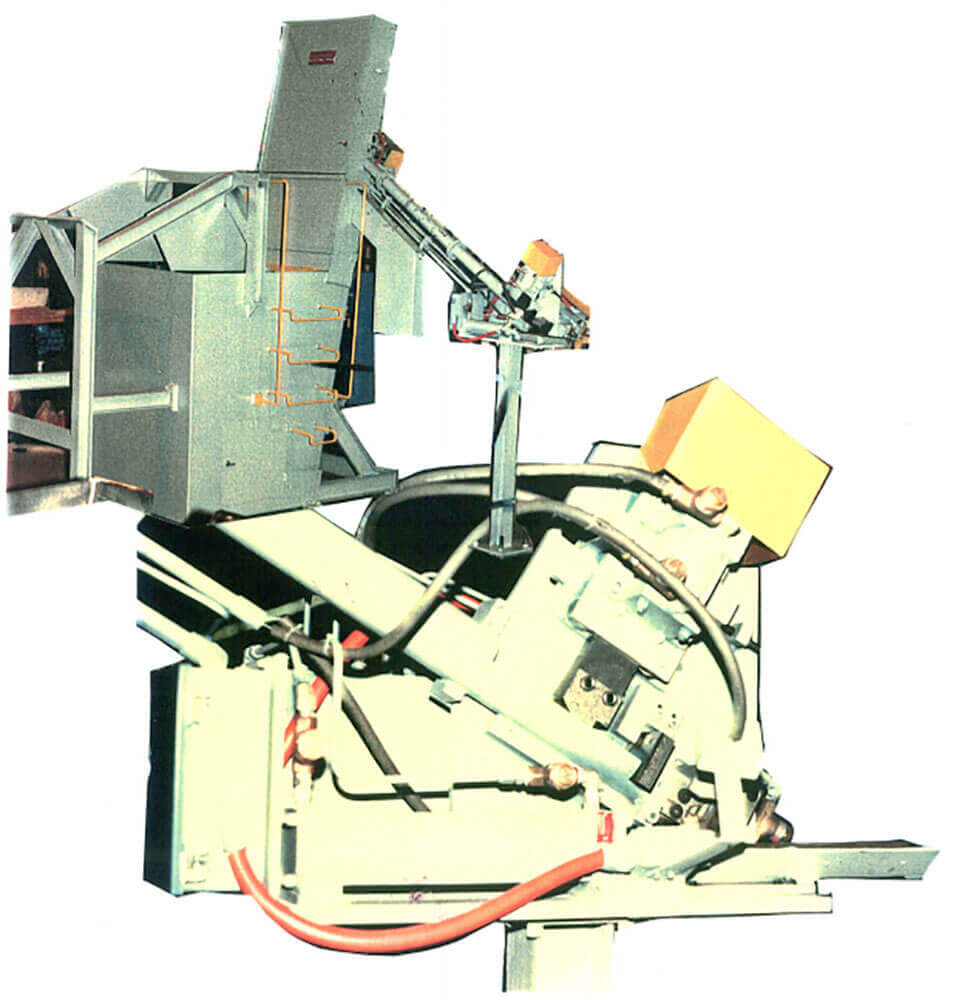

10532: PROJECT FEEDING STEEL BILLETS INTO INDUCTION HEATER

Feedall Model

Model 2500 HD

APPLICATION

Feed from a random loaded floor mounted hopper sheared steel billets, 1.937 to 2.625″ DIA. X 2.00 to 3.25″ LG. The billets will be oriented into a single end to end stream, then transferred one at a time rolling into a pusher device, which will advance each billet to an induction coil at 60″ above the floor at a rate of 350 to 450 per hour for forging.

12″ wide elevator belt, 30 CU. FT. Hopper.

DWG PD 7152.

WIDTH

12" wide elevator beltFEED RATE

350 to 450 per hour for forging Menu

Menu