Up to 36-inch long bars

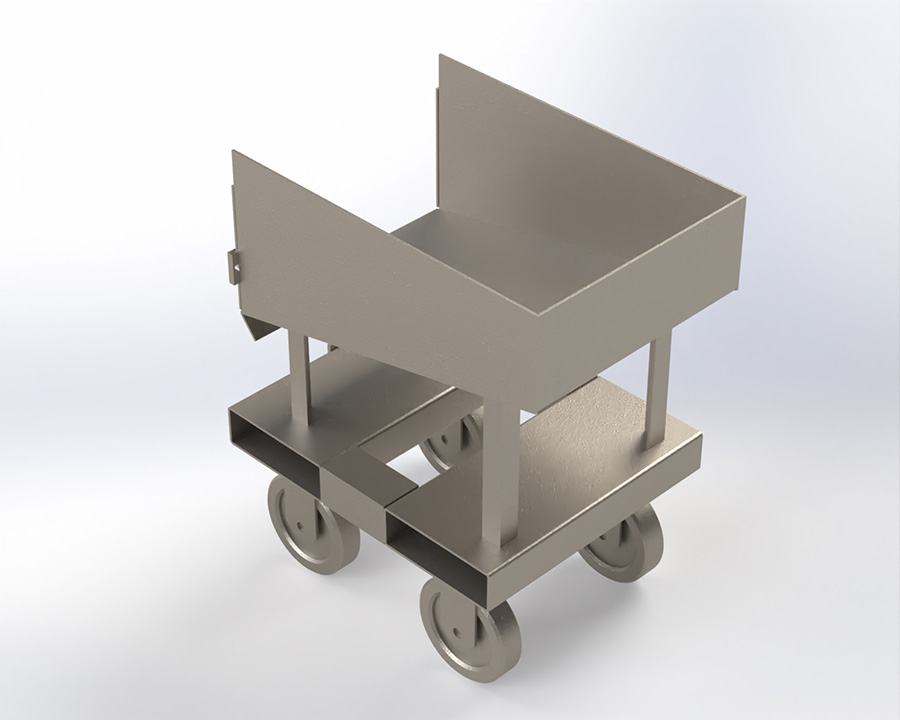

2212, 2224, 2236

Strengthened Automatic Bar Feeder Capabilities

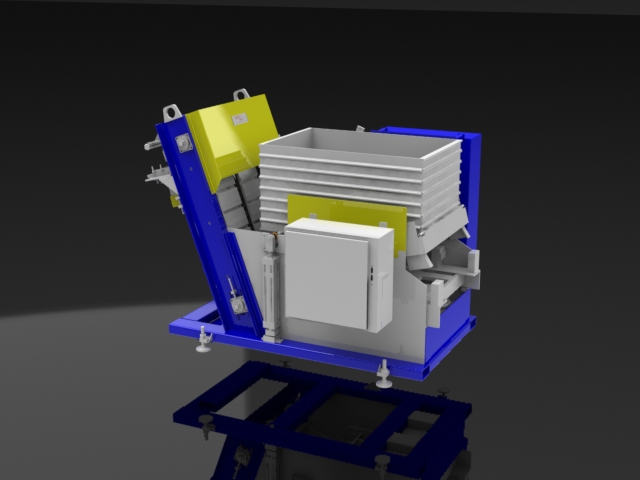

Feedall offers a complete line of hopper, or floor-loaded, bar feeders that automatically handle sliding, rolling, or headed parts. These units are well suited for non-mar applications when parts are finished or in a pre-heat-treated state. The automatic feeding process is more cost-effective and efficient as it eliminates hand labor and saves time lost from handling parts manually.

The 2200 series of the Retriever line features a core floor/hopper loaded automatic bar feeder design built to handle tubes, cut-to-length bars, and machined parts with diameter ranges within a 2 to 1 ratio. Part lengths best suited for these models range from 12 to 36 inches, depending on the specific unit. Parts can be hand stacked, bundle loaded, or, with modifications to the hopper, loaded from a previous operation via a conveyor.

Overview

The automatic bar feeder functionality of the floor-loaded components in the Retriever line includes low noise levels due to zero circulation of parts. Parts fed by these units include steering racks, strut piston rods, copy machine rolls, axle shafts, and many other bar & shaft shaped parts. The feeder works by elevating the parts on singular pads; they are then discharged rolling into a magazine. The parts then escape, rolling, to a cross conveyor, pusher device, walking beam, or customer tracking.

Each model of the floor loaded automatic bar feeder line corresponds roughly to the size of parts handled. Consult with our team for more detailed differences:

- Retriever 2212 — up to 12 inches

- Retriever 2224 — up to 24 inches

- Retriever 2236 — up to 36 inches

Like all of our automation equipment, these automatic bar feeders can be optimized and customized completely per your requirements. Features and options for these feeders include:

- Easy access hopper side cut out for part loading (optional hinged door)

- Vertical elevator with two strands of roller conveyor chain

- Bolt-on cleat pads machined for each application part range

- Boston D.C. variable speed elevator drive

- Adjustable rear magazine and pneumatic escapement device

- Telescoping ramp from magazine to conveyor (for centerless grinder)

- Ball bushing conveyor mountings (for centerless grinder)

- Cross–Feed Conveyors

- Part Transfers, Qualifiers & Pushers

- Powered Wheels