Understanding the Types of Feeders in Automation

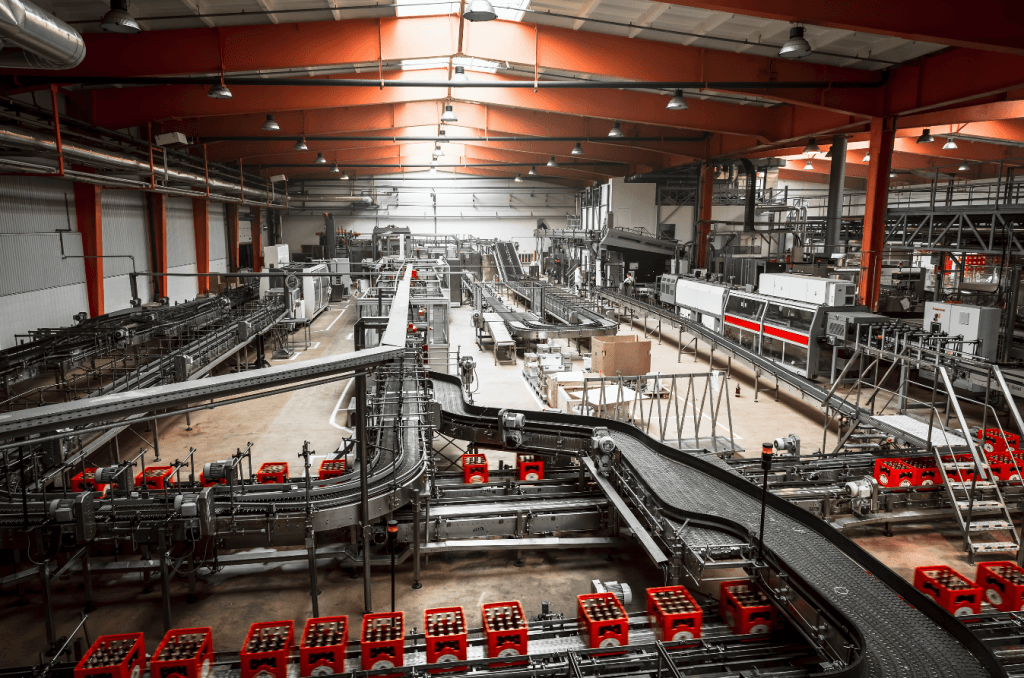

Every production company follows its own unique practices, workflows, and internal procedures to achieve a specific product result or outcome. To support these custom processes, their production environment part feeders should be unique as well. There are a number of different types of feeders in automation ranging from simple input/output configurations to more advanced options that adjust operational productivity based on the complexity of parts being fed and infeed/escapement requirements.

With so many different types of feeders in automation environments, it’s important that you utilize a feeder that not only performs the necessary function for the part being fed but also advances operational productivity in a facility. This is because feeders are just one part of an overall production chain, and while at times they don’t seem critical, they typically set the overall efficiency and throughput of the production environment. Ways this might be achieved begin with custom design and engineering from a reliable automated feeder manufacturer.

To demonstrate the fact that one size does not fit all applications, and that the ideal feeder for your operation is just a conversation away, we’ve gathered a few examples of highly customized and industry-leading feeders. We’ll explain what they do, what their key features and functions are, and what distinguishes them for businesses that use them.

Three Types of Feeders in Automation

1. Model 4800 Heavy Duty Billet Feeder

The Feedall Model 4800 Heavy Duty Billet Feeder is an industry-leading type of feeder in automation for a number of reasons. Steel billets are required as part of the overall steel production process and can be quite large — often up to 6” in diameter and 30” long. Needless to say, safely and efficiently handling billets presents a unique challenge to forging facilities. With the Model 4800, production teams don’t have to worry about manually feeding these large billets into the next process such as induction heaters or robotic automation cells for press loading.

The Feedall Model 4800 Heavy Duty Billet Feeder is an industry-leading type of feeder in automation for a number of reasons. Steel billets are required as part of the overall steel production process and can be quite large — often up to 6” in diameter and 30” long. Needless to say, safely and efficiently handling billets presents a unique challenge to forging facilities. With the Model 4800, production teams don’t have to worry about manually feeding these large billets into the next process such as induction heaters or robotic automation cells for press loading.

The 4800 feeder can seamlessly integrate from a cut-off saw so the billets are then dumped — up to 10,000 lb. worth — and properly metered into the feeder hopper. This integrated system is designed to take the full impact of the parts, preserving the life expectancy of the feeding system. Adjustable and replaceable cleats allow for different part configurations, and its overall design and engineering allow it to be easily configured for new tools and programs. This flexibility for adjustment allows for greater paypack on the overall capital purchase versus a vibratory bowl.

Learn more about the Model 4800 Heavy Duty Billet Feeder here.

2. Model 1700 Magazine Style Automatic Feeder

The Feedall Model 1700 Magazine Style Automatic Feeder was the first bar and tube feeder available in the market. These types of feeders in automation allow companies to stock a full shift of parts which are then automatically fed into a secondary operation, such as robotic pick and place. The machine is built with long-term maintenance, longevity, and flexibility in mind. The majority of components are bolted on as opposed to welded on, and all tooling is heat-treated and features a black oxide coating for durability.

The Feedall Model 1700 Magazine Style Automatic Feeder was the first bar and tube feeder available in the market. These types of feeders in automation allow companies to stock a full shift of parts which are then automatically fed into a secondary operation, such as robotic pick and place. The machine is built with long-term maintenance, longevity, and flexibility in mind. The majority of components are bolted on as opposed to welded on, and all tooling is heat-treated and features a black oxide coating for durability.

The proprietary soft agitation feed design guarantees positive singulation of parts, and the load system allows operators to easily fill the magazine. The machine was also engineered for acoustics, keeping the Db level below 85 and allowing operators to use this machine without earplugs — which is lower than vibratory bowls. Quick-adjust hardware allows for rapid part diameter and length changes as well.

Learn more about the Model 1700 Magazine Style Automatic Feeder.

3. Model 2500 Automatic Hopper Feeder

The Feedall Model 2500 Automatic Hopper Feeder is an industry leader in random parts bin feeding. This machine is designed to control and orient parts from a random bin, allowing companies to achieve unprecedented levels of increased up-time while reducing labor costs associated with manually loading. Parts are oriented and placed in a chute with right- or left-hand takeoff or two-track delivery.

The Feedall Model 2500 Automatic Hopper Feeder is an industry leader in random parts bin feeding. This machine is designed to control and orient parts from a random bin, allowing companies to achieve unprecedented levels of increased up-time while reducing labor costs associated with manually loading. Parts are oriented and placed in a chute with right- or left-hand takeoff or two-track delivery.

As with many other Feedall-designed types of feeders in automation, the 2500 automatic hopper feeder is custom-engineered to customers’ exact specifications. Part elevator cleats and spacing are designed precisely for the part being fed, and all components are hardened for maximum longevity and minimum maintenance. Machines are built for durability with material thickness of ¼ inch or greater — typically surpassing industry standards and ensuring it performs well for decades.

Learn more about the Model 2500 Automatic Hopper Feeder and its variations.

What Type of Feeder in Automation is Right for You?

The above types of feeders in automation are just a small sampling of the options available at Feedall Automation. As one of the leading providers of flexible feeders, conveyor systems, material handling solutions, and robotic automation accessories, everything we provide for our customers is designed and engineered to their specific needs.

We begin with a standard feeder configuration which is then modified by our engineering team to meet your part feeding, material loading, escapement, and overall process requirements. The result is a one-of-a-kind feeding solution that not only meets your needs but streamlines your production process in multiple ways. Examples include:

- Reducing the time between production processes

- Increasing feeding quantity for more production capacity

- Reducing the labor needed to load or manage parts

- Improving safety metrics and protecting workers

- Reducing the overall cost of ownership with reduced maintenance

If you’ve been exploring the different types of feeders in automation and are realizing that you need a custom solution, put our 75 years of experience to the test. We will work closely with you to design a solution that not only meets your needs but enhances performance, improves reliability, and more.

Contact our team today to learn more about the different types of feeders in automation and how we can build a solution for your needs.

Menu

Menu