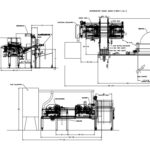

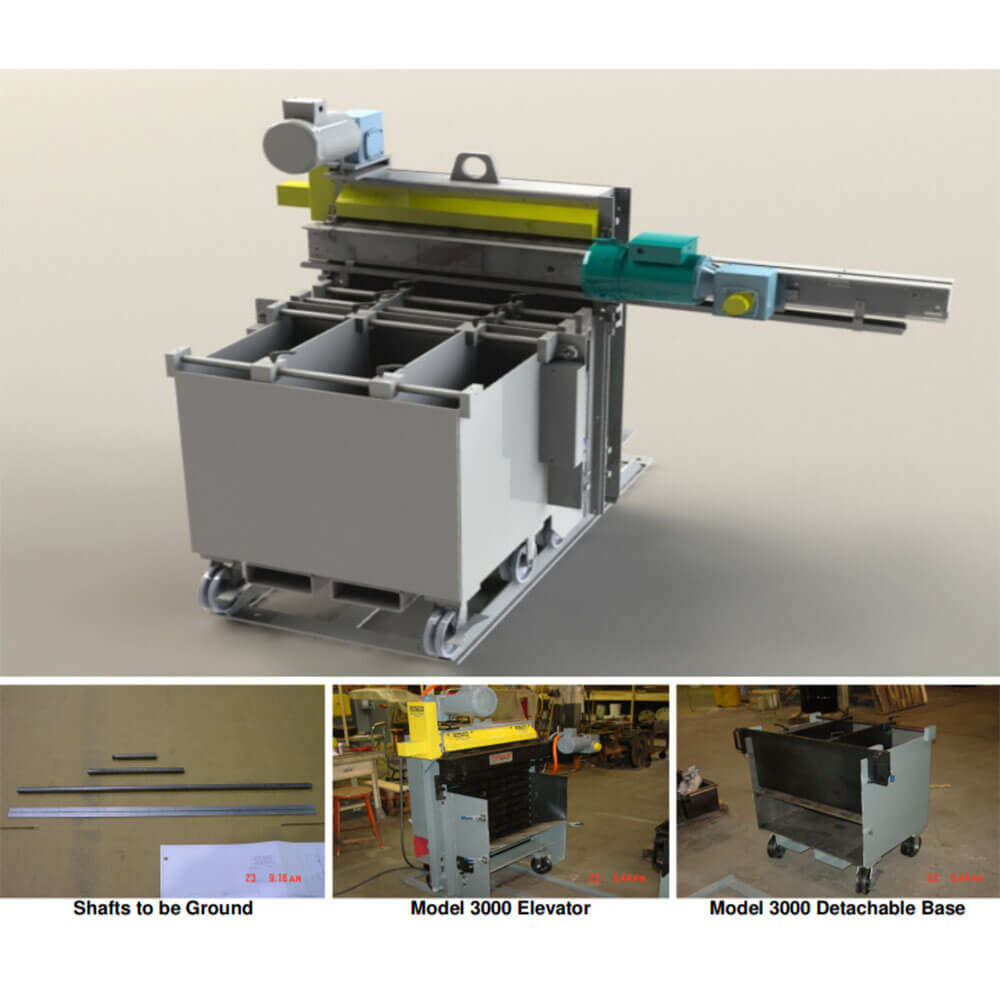

Hopper Feeder (Small Parts)

Model 2000 / 3000 / 3600

Model-3000-Hopper-Feeder-for-Centerless-Grinders.pdf

Hopper Part Feeder – 2000-3000-3600-4800

Hopper Feeder and Models

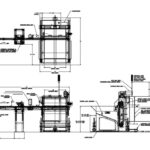

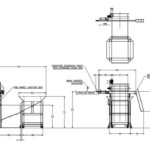

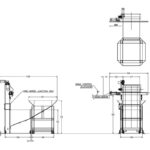

Model 2000 / 3000 / 3600 Hopper Part Feeders are used for feeding cylindrical type parts such as cut bars, tubes, and shafts with diameter range within a 2:1 ratio. Parts are bulk loaded or hand stacked in multiple rows when part orientation is required. This feeder is designed for higher feed rates and gentle handling of the parts with lower noise levels. By design this feeder naturally orients parts with the elevator belt, thus eliminating recirculation of misoriented parts. Our Model 1650 Cross-Feed Conveyor mounted to the front of the elevator allows continuous flow in an end-to-end orientation.

Parts are fed to various types of equipment; centerless grinders, thread rollers, induction heaters for selective hardening or preheating for forging and many other applications. For each application, a feeder is sized and equipped with various tooling and options to suit. This type of feeder is designed for higher feed rates and gentle handling of the parts with lower noise levels. The hoppers are either bulk loaded or parts may be hand stacked in multiple rows when the orientation of the part is required or when parts are soft and bulk loading may cause the part to part damage.

Menu

Menu