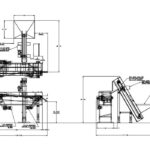

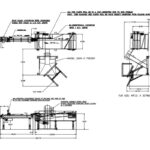

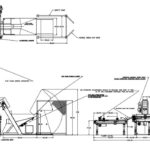

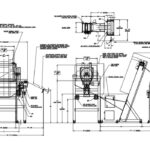

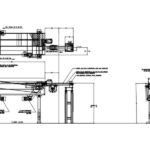

Bidirectional Orienting Conveyors

Model 1500

BIDIRECTIONAL-ORIENTING-CONVEYOR.pdf

Automated Bi-flow Orienting Conveyors

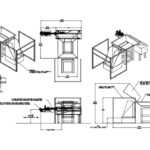

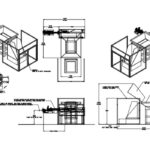

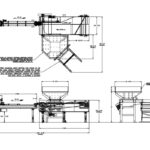

Feedall Model 1500 Bidirectional Orienting Conveyors were designed for gentle/non-mar orienting and non-orienting parts feeding. This feeder is easily adjusted for various part size ranges. Part shapes may be disc, ring, cylindrical, shaft type, solid or tubular. Parts are loaded from tote pans, bulk floor hoppers or by conveyors from a previous operation. The Feedall Model 1500 bidirectional orienting conveyor may be used to feed grinders, selective induction hardeners, thread rollers, forging and extrusion presses, assembly machines and many other parts feeding applications.

- Gentle, Non-Mar Parts Feeding

- High Speed, Low Noise Levels

- Fast Set Ups With Adjustable Tooling

- Flexible Application Feeder Design

Menu

Menu