Orienting Part Feeders

Orienting Part Feeders for Automation Systems

Hardworking Equipment

Feedall Automation specializes in premium orienting parts feeders made with the highest quality standards. Our equipment is known in the market as being “bullet-proof” because it is built to run 24/7, 365 days per year.

Custom Orienting Part Feeders

We create orienting part feeders and material handling solutions specific to the needs of your company and industry. When you’re faced with the difficult task of purchasing specialized automation equipment, you can take comfort in knowing that our designs reflect more than 70 years of successful real-world applications.

Types of Orienting Part Feeders

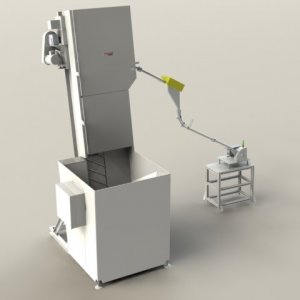

MODEL 2400

Random Loaded Feeders (Small Parts)

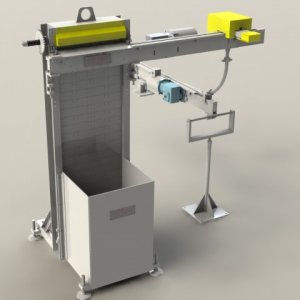

MODELS 2500 / 2600 / 2700

Random Loaded Feeders (Heavy Duty)

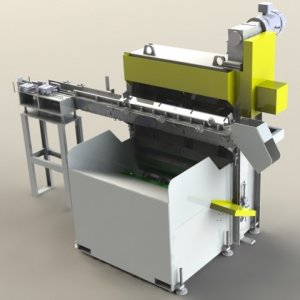

MODELS 2000 / 3000 / 3600

Hopper Feeders

MODEL 4800

Heavy Duty Billet Feeders

Menu

Menu